Top & Bottom Automatic Labeling

Improve Labeling Efficiency

We can label the following:

- Case-ready trays

- Shrink-wrapped products

- Cryovac-ed® product

- Whole or packaged fruits and vegetables

- Cheese and dairy products

- Customized applications to fit your products

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

Our Top & Bottom Labeling Systems provide automatic, precise label placement without the need for costly manual labor. Label information can be preprinted on the label, or can be printed during the labeling process.

Features & Benefits:

- Elimination of unnecessary manual labor maximizes profits

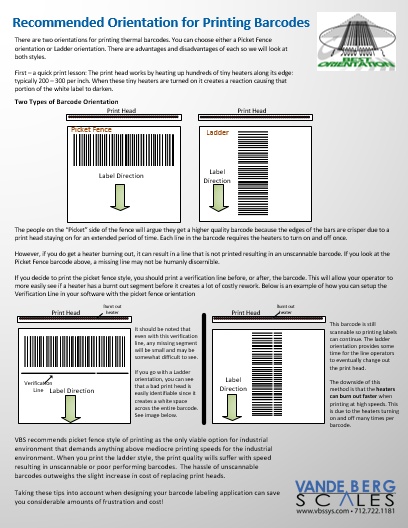

- Accurate label placement ensures a consistent looking product, which helps promote the brand

- Adjustable label applicator permits quick label roll replacement, regardless of label type or size

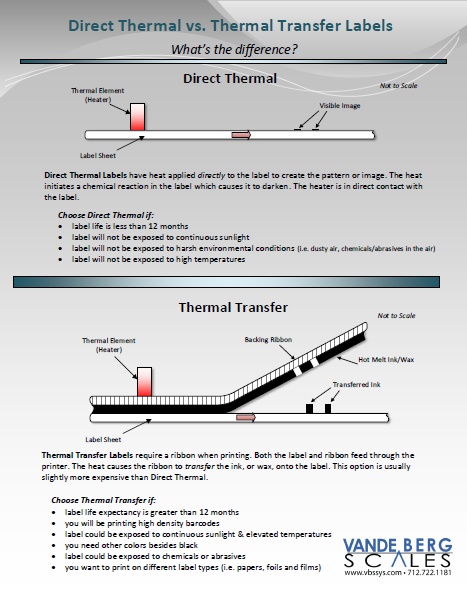

- Machines incorporate either pre-printed labels, or on-demand label printing

- Industry available parts save you time and money on maintenance and repairs

Top & Bottom Labeling Features:

FAQ

Yes. We do this by means of an pacing conveyor and guide rails.

This is highly dependent on size of the label & label content. A safe number is around 100-130 per minute if no printing is required.

Yes. However, the label contents must be stored on our system (SDS Controller). Even if the plant network goes down our system will continue to weigh packages and print a label. When the network is back up, it can access our on-board SQL database to pull the weight information for each package.

Primary Components

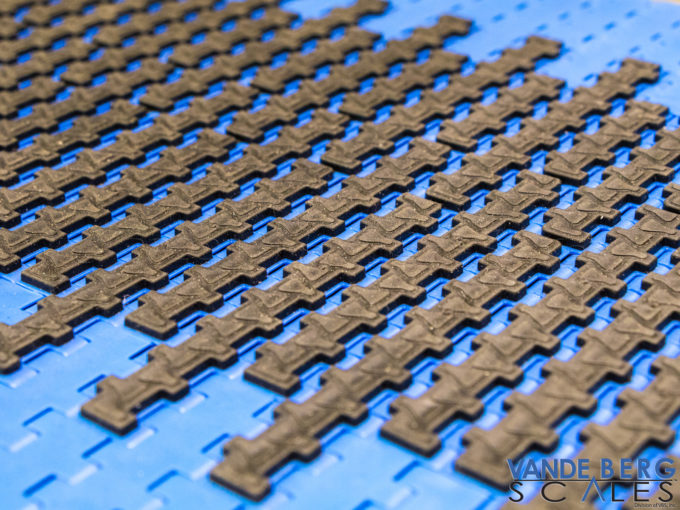

- Conveyor with product guides to move products past labeling applicators

- Top and/or Bottom Labeler to apply labels to product

- Optional Printer for on-demand real-time printing

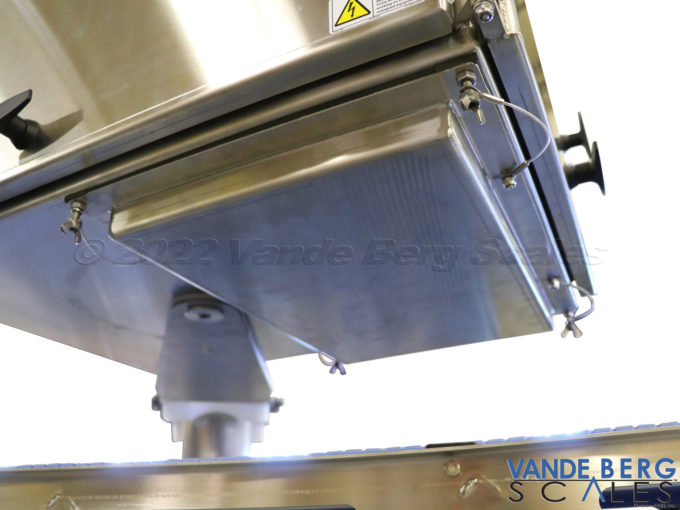

See how bottom labels applied to packages:

For applications needing a label on both the top and bottom of the package, Vande Berg Scales will build a combination top/bottom label applicator that exactly matches your needs.

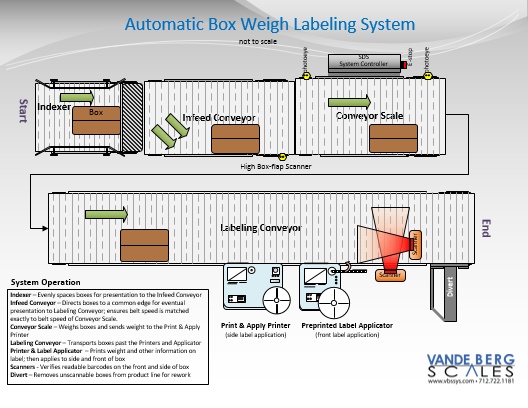

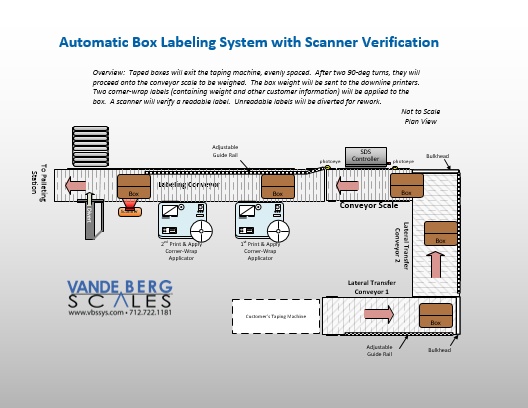

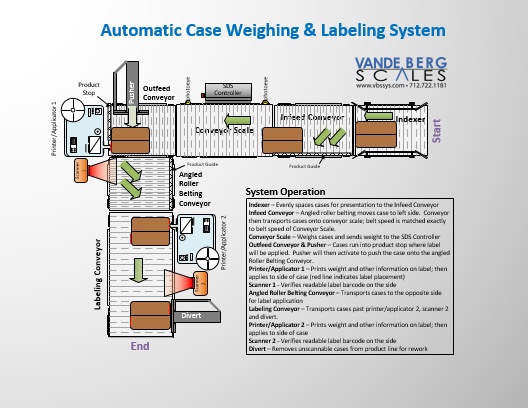

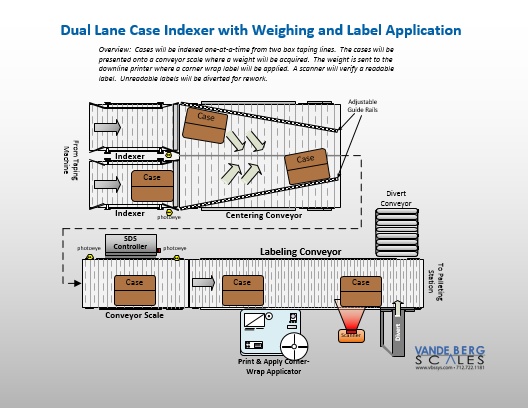

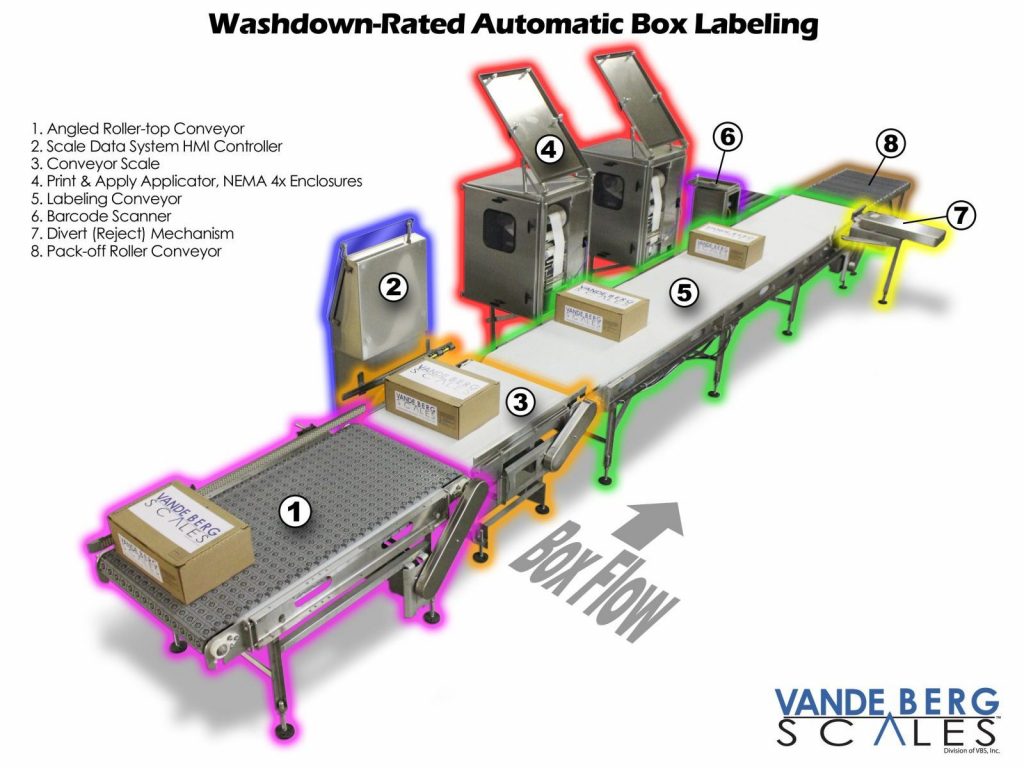

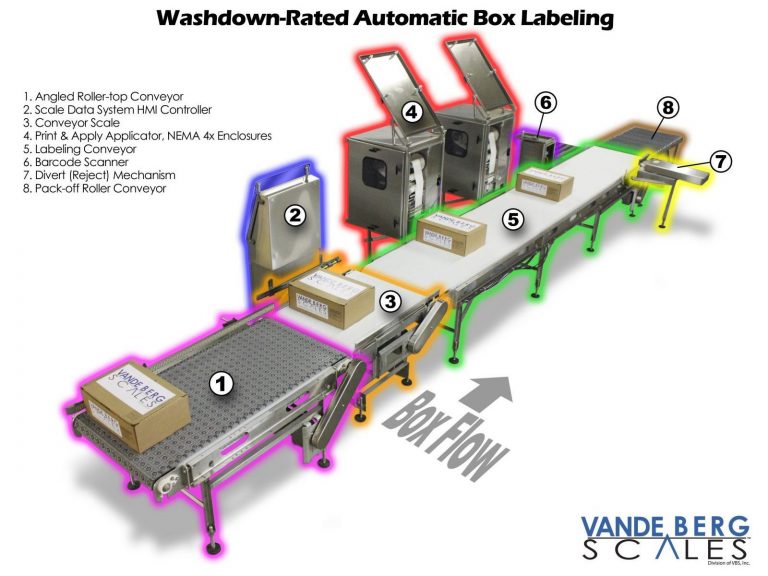

Need a system that can label boxes? See system below.

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.