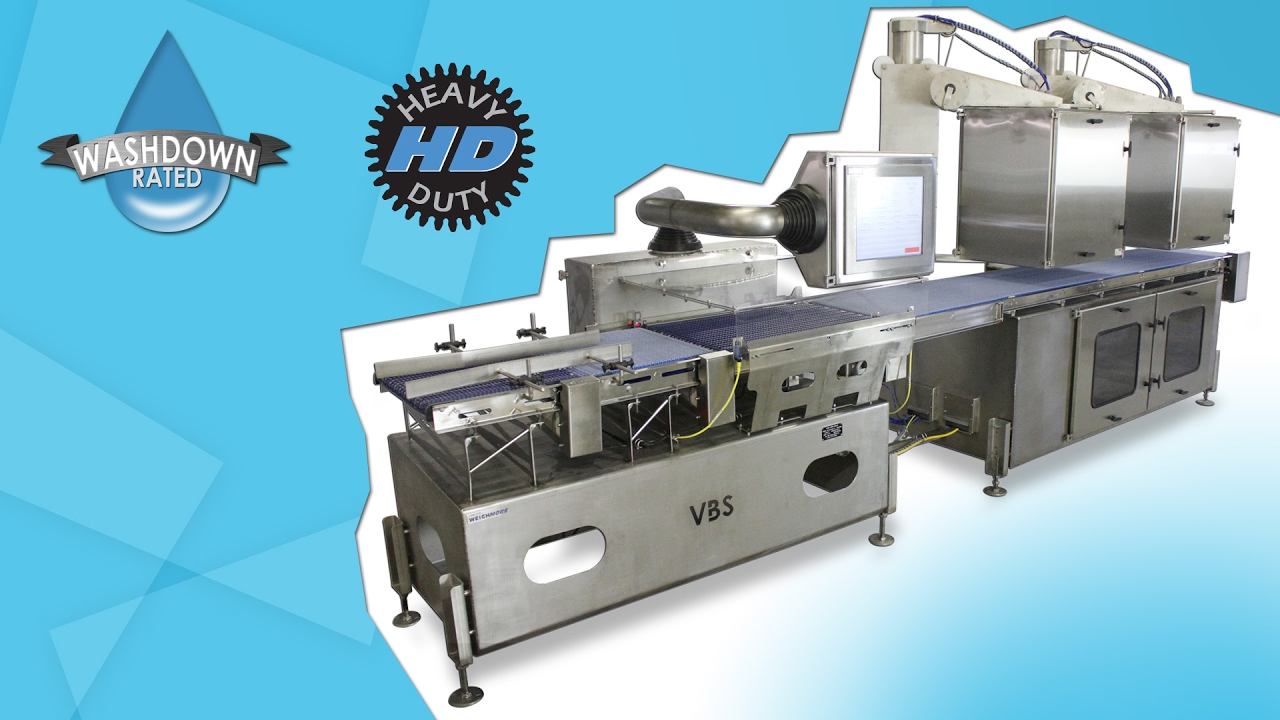

Weigh Price Labeler

Washdown & Heavy Gauge – An industry first

Weigh Price Labeling Videos

Avoid annoying ads by watching videos here. ↓

WPL Videos

4:34

4:29

5:59

3:48

1:58

2:56

2:55

3:51

1:47

3:48

4:09

Additional Features & Benefits

- Can be integrated into a network, or used as a stand-alone machine

- Easily setup hotkeys for common products (up to 200 are possible)

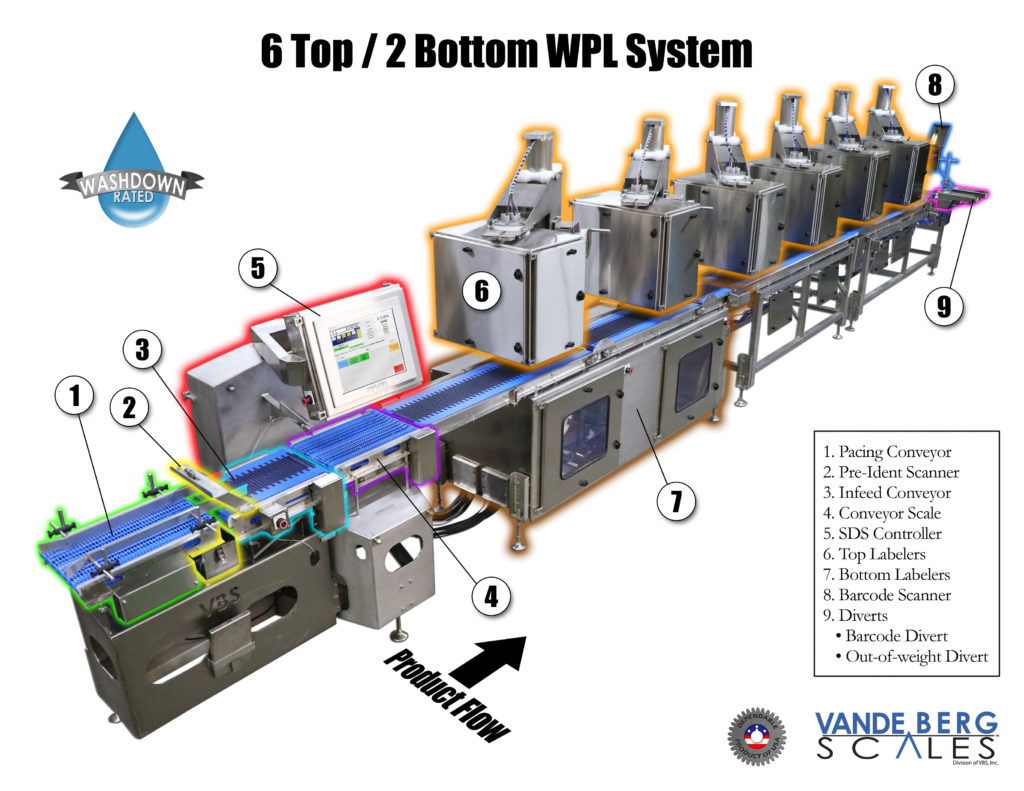

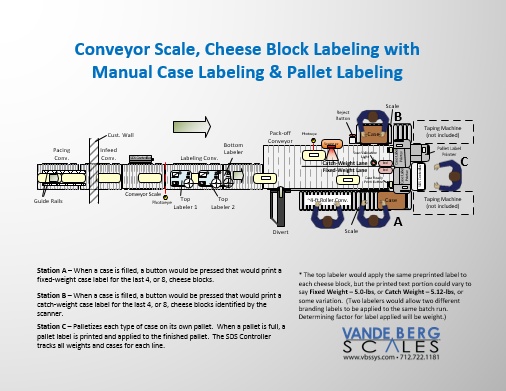

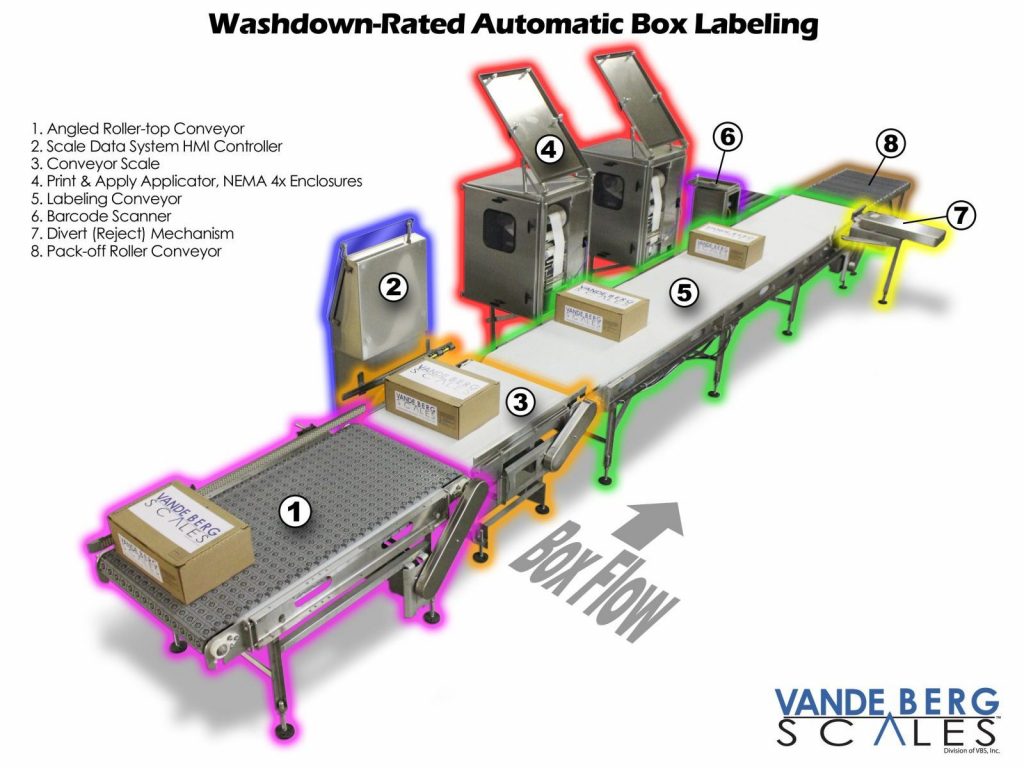

- Configurable to your needs with options of single or multiple upper & lower printer-applicators or just pre-printed label applicators.

WPL Equipment Specifications

- Construction: Heavy-gauge 304 Stainless Steel

- Interface: 17-inch HMI Color Touchscreen

- Controller: Embedded Operating System

- Data Export: configurable to your needs (i.e. SQL, .csv, .xls, etc…)

- Communication: Ethernet TCP/IP, RS-232, RS-485/RS-422

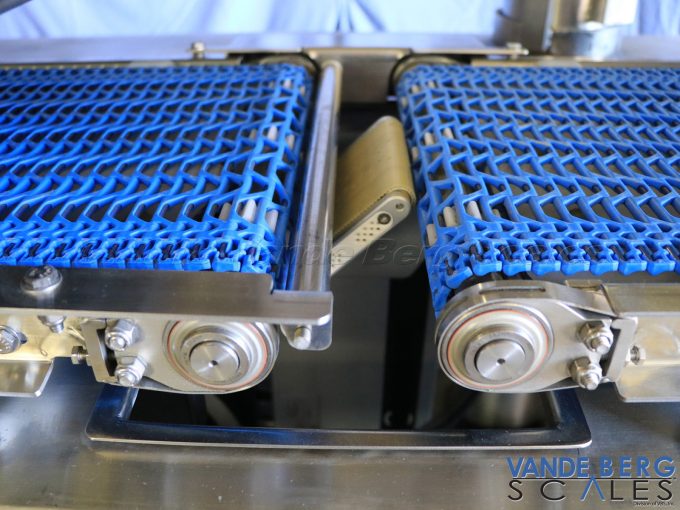

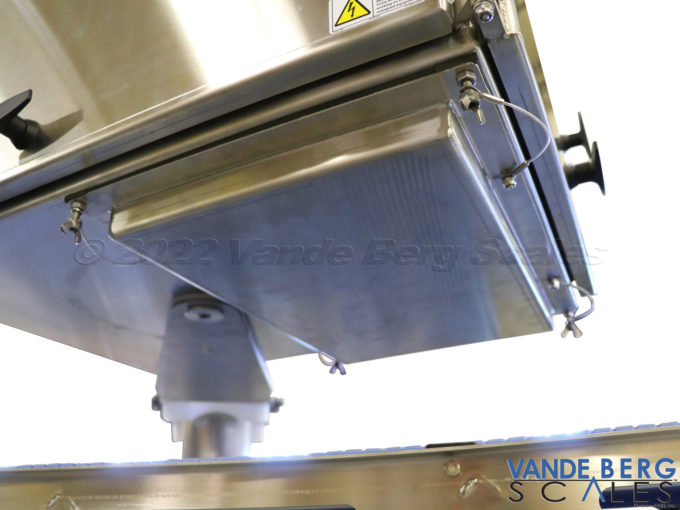

Introducing the industry’s first washdown automatic weigh price labeler! The result is less expensive component replacement from a washdown crew’s carelessness. Unit is made of 3/16″ SS plate, which is unrivaled in the WPL industry.

Features & Benefits:

- Heavy-hose washdown compatibility (ENTIRE unit)

- Rigid heavy-gauge 304 stainless steel construction

- Competitive purchasing costs

- Undisputed low-cost replacement parts

- No hostage guarantee – unit is built from industry available parts so you can find replacements within days, not weeks or months

- Technically intelligent yet easy-to-operate 17-inch color touchscreen HMI

Weigh Price Labeler Features:

FAQ

Yes – We can customize the weigh price labeler equipment to your exact specifications. This results in optimized speed and accuracy for maximum throughput. We can also add preident scanning, scanning verification or a divert if needed.

Yes. The system is designed to be stand-alone. If we are connected to your network, we recommend the label contents be stored on our system (SDS Controller). Even if the plant network goes down our system will continue to weigh boxes and print a label. When the network is back up, personnel can access our on-board SQL database to pull the weight information for each package.

Advantages of Automatic Weigh Price Labeling

Advantages of Automatic Weigh Price Labeling

- Reduces product give-away to zero since the package is priced based on exact weight (fixed weight labeling does not allow this)

- Significantly reduces labor vs. a manual weigh price labeling machine (label 1,000’s of products per hour vs. just a few hundred)

- Correct label placement every time

- Clerking errors are virtually eliminated

- More hygienic and sanitary since humans are not handling the product

- All weighed/priced packages are stored in a database for statistical weight and histogram analysis

Label Designer Software (Included)

Supports most industry standard barcodes such as:

- 2D Barcodes (call us for format type)

- Code 39: Variable length, alpha-numeric

- UPC A: 12 digits, numeric only

- UPC E: 7 digits, numeric only

- I-2 of 5: Variable length, numeric only

- Code 128 Type A & B: Variable length, alpha-numeric

- Code 128 Type C: Variable length, numeric only, number

How do I create a label & print it?

Simply create the label with our Label Designer software on any Windows® desktop computer, transfer to a USB storage device and then upload to our Scale Data System (SDS). The SDS Controller can simultaneously store several labels for quick selection based on product. You can also test print a label on any compatible label printer to preview before transferring to the SDS.

Features & Benefits:

- On-screen label format display (WYSIWYG)

- User-defined product labels limited only to disk space

- Product specific or universal label formatting

- Compatible with Windows® XP, 7 & 10 operating system

- Product definable fields

- Import company-specific or USDA bitmaps

- Create line, box and circle shapes

- Capable of batch printing fixed weight labels

SDS Controller which accepts the label format for eventual label printing on a box or package. Learn more about the SDS Controller.

Additional Videos

We make the toughest Automatic Weigh Price Labelers in the world!

Pork Box Weigh Price Labeling System with Scanning & Divert

Pork Tenderloin Weigh Price Labeling System with Backup Applicator

Super-Fast Weigh Price Labeling - 13 Amazing Features

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.