In-Motion Checkweigher

Reduce Your Product Give-Away

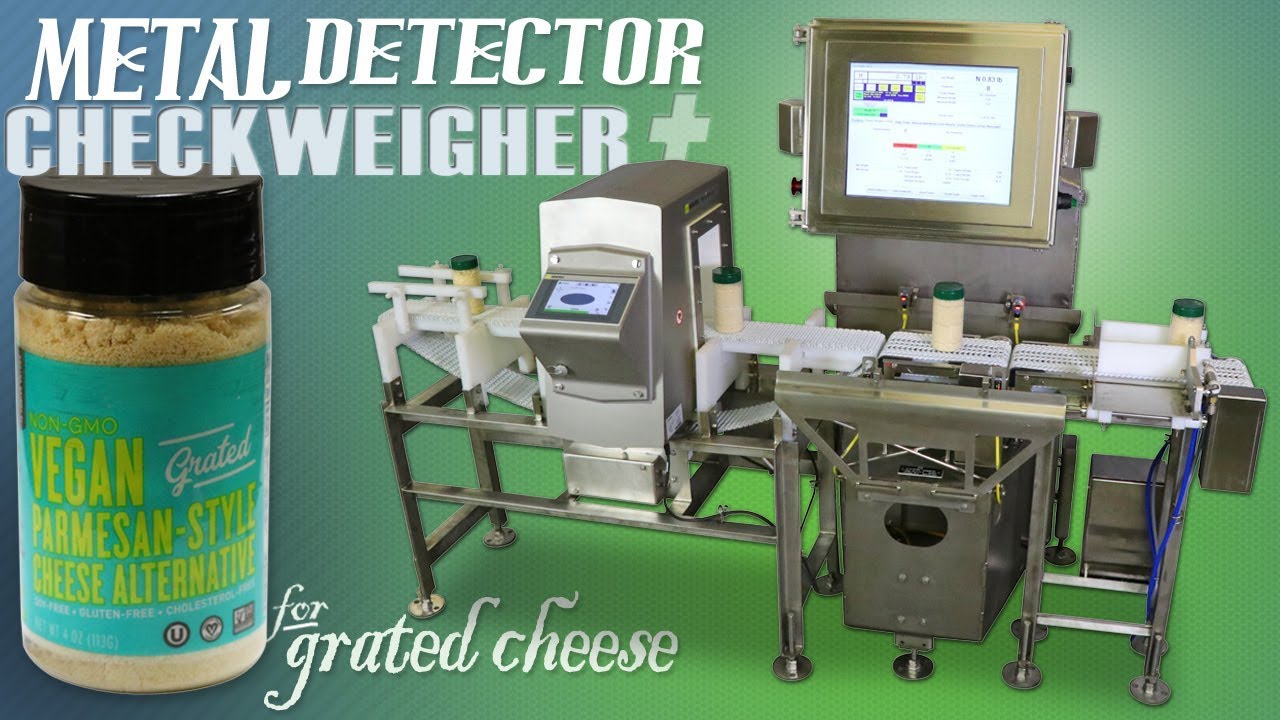

Checkweigher Videos

Avoid annoying ads by watching videos here. ↓

Checkweigher Videos

3:06

2:47

2:41

2:35

3:41

2:53

3:12

3:47

3:38

3:14

2:50

Need Customization?

We can customize a checkweigher to your exact specifications. This results in optimized speed and accuracy for maximum throughput.

Tired of Small Displays?

VBS integrates an impressive standard 17″ Human Machine Interface display for almost unlimited reporting and display options. Large displays also reduce deep system settings that are hard to find.

No parts pricing sucker punches!

Our Automatic In-Motion (Dynamic) Checkweighers employ state-of-the-art features which make them the best value in the industry. Our units give you an accurately weighed product that you and your customers can trust.

Features & Benefits:

- Reduces product “giveaway” which saves you money

- Reduces false rejects and rework thereby saving time and money

- Incorporates an extremely durable and cost effective load cell vs. magnetic force restoration technology that can be costly, delicate and complicated.

- Most units are backwards compatible ensuring replacement parts will be available for years vs. having to replace the entire unit due to discontinued product line excuses.

- Off-the-shelf parts ensure you can easily source replacement components so you are back in operation.

Checkweigher Design Features:

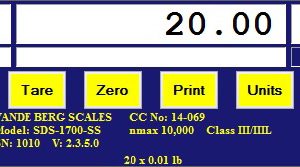

Capacity x Resolution (Standard)

200 lb x 0.1 lb

100 lb x 0.05 lb

40 lb x 0.02 lb

20 lb x 0.01 lb

10 lb x 0.005 lb

Capacity x Resolution (Metric)

100 kg x 0.05 kg

40 kg x 0.02 kg

20 kg x 0.01 kg

10 kg x 0.005 kg

4 kg x 0.002 kg

Additional Features

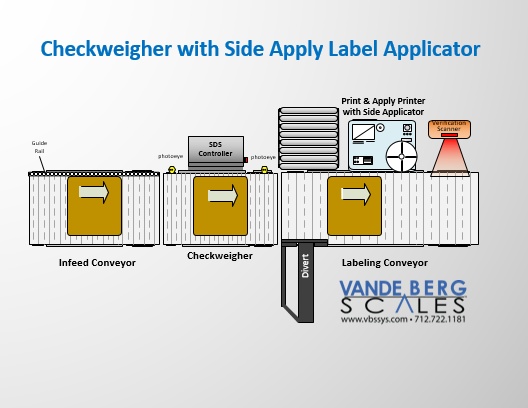

- VFD to automatically change conveyor speed based on product length. This allows optimum weighment of each type of product.

- Ethernet TCP/IP & Serial (RS-232) communication is standard. Ethernet IP is additional.

- Large 17-inch touchscreen HMI for ease of operator viewing and interface

- Draft shield protects scale from environment triggered weighing errors

FAQ

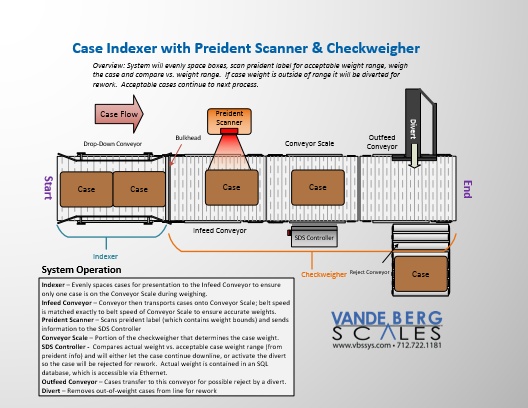

A conveyor scale simply acquires the weight and send it out.

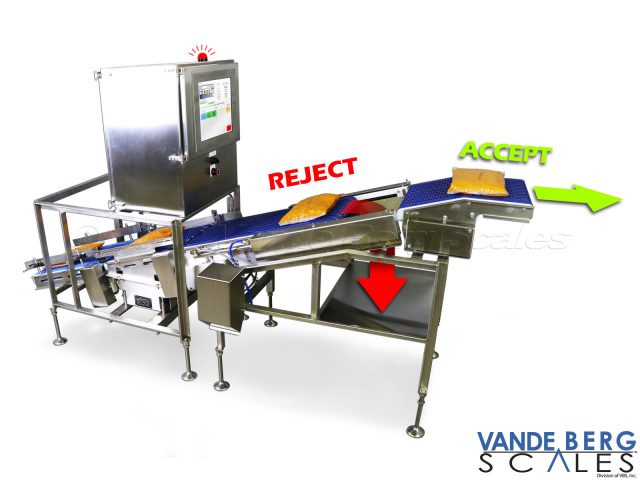

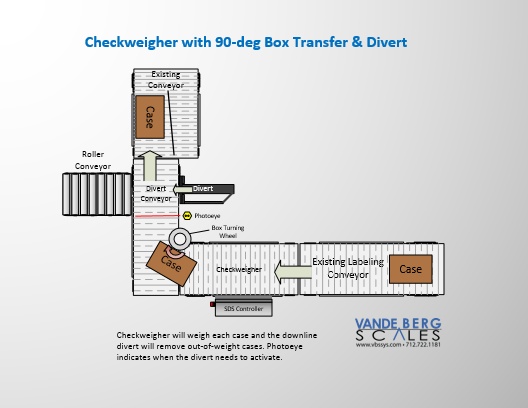

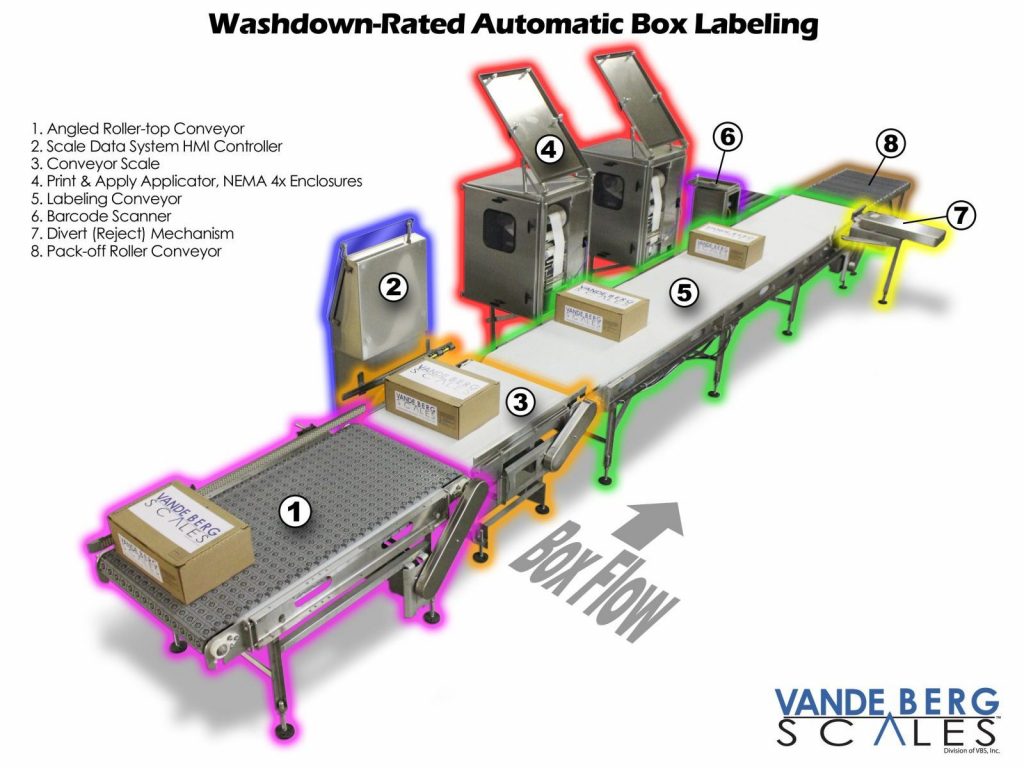

An automatic checkweigher will acquire the weight, compare the weight against an upper and lower limit, and then take an action. Just a few examples of actions are illuminate a light, stop a conveyor or divert the product off the line for rework (most popular). Our checkweigher will also store the weight for later analysis.

No. Stopping the conveyor for each product would significantly increase component wear & tear, and reduce the throughput.

Even while in motion our NTEP certified scale and algorithm will accurately determine the weight of the weight of the product.

Most of the time, No. A checkweigher is primarily used to validate how well a package, or container, was filled upstream. The upstream scale, or filling machine, needs to be NTEP. However, VBS is one of the few companies that offer an NTEP certified checkweigher.

Yes to both. We offer RS-232 (serial) and Ethernet communication as standard. You can see the database being populated or export the data after a finished run. (Ethernet IP option is also available.)

An inline checkweigher can weigh product in the conveyor line without having to pull the product off of the line and place it on a scale. This allows 100% product weight sampling.

Innovative In-line Checkweigher Design Elements

Single drive design virtually eliminates the harmonics that can result when you have dual drives (one on each conveyor end). Harmonics often develop when motor speeds are not precisely matched. The result is internal scale movements that can significantly affect weighing accuracy.

It took years to figure out, but we finally came up with a single load cell design. The result is a scale that is more reliable and less cost. The reduced cost part is obvious, but what about the reliability? Most scales have 4 load cells (one of each corner), so when one load cell fails, the entire scale is out of commission. Having a single load cell design significantly reduces the chances of overall load cell failure.

Since we only have one load cell, we can reduce cost by eliminating the junction box.

Moment forces need to be considered with a single load cell design. VBS has engineered a unique multi-angled bracing that consistently transfers weight to the middle, where the load cell is located.

Our Experience

- Poultry, boneless breasts, tenders, lobes, wings or any chicken component

- Beef, hamburger patties, ground beef, loaves, chubs, brisket, sirloin, beef ribs, roast (any type of meat)

- Pork chops, bacon, pork bellies, baby back ribs, St. Louis ribs, ham, loins, picnics, or any pig product

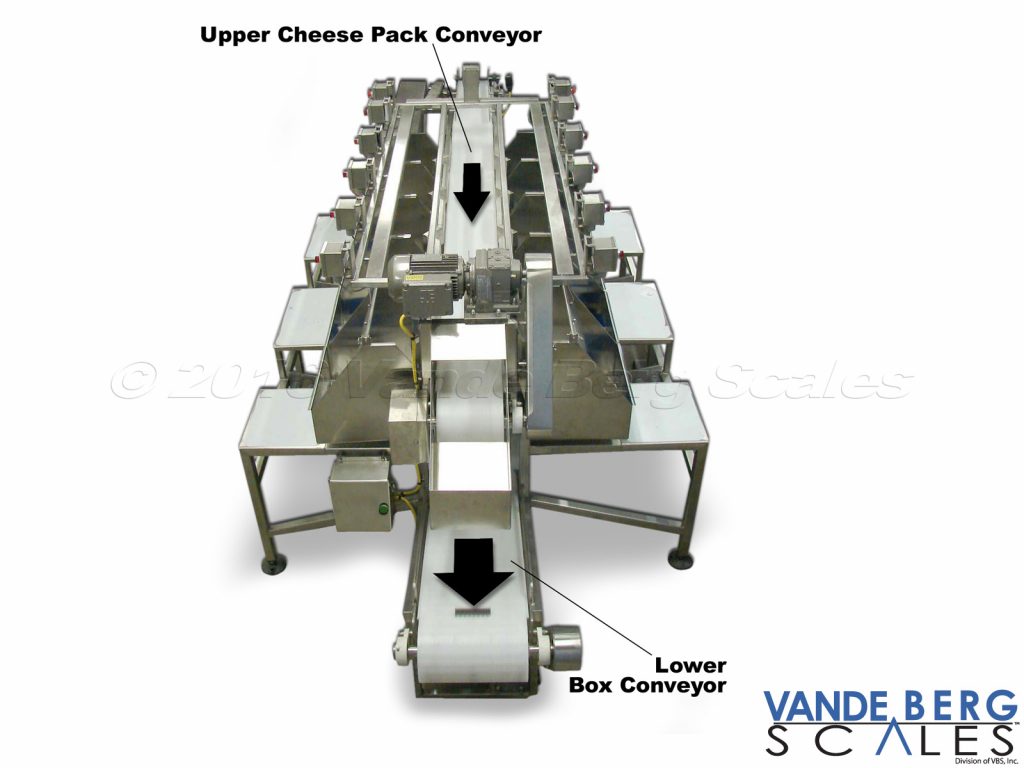

- Dairy, cheese, milk, cream, yogurt

- Turkey, drumsticks, thighs, leg quarters, lamb chops, duck

- Boxes, bags, sacks, paint cans, cans, bottles, pouches, etc.

- Corn/bean seed, bag, potatos, onions, flower bulbs

Additional In-Line Checkweigher Videos

Incline Checkweigher with Quick-Acting Inline Divert

Cheese In-line Checkweigher with Dual Diverts and Machine Feedback

Dual-Lane Raw Chicken Checkweigher

Checkweigher Construction Styles

(adder for NTEP Certification)

Style 1

Aluminum

[Light-duty applications bolted; heavy-duty applications welded]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Brake parts are stainless steel

- Non-washdown painted motors & bearings

- Aluminum loadcell

Style 2

Stainless Steel

[non-washdown; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Non-washdown painted motors & bearings

- Aluminum loadcell

Style 3

Stainless Steel

[washdown rated; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- Epoxy painted NEMA-4X motor & gearbox

- Aluminum loadcell

Style 4

Stainless Steel

[washdown rated; non-food grade]

- Continuous weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- Epoxy painted NEMA-4X motor & gearbox

- Aluminum loadcell

Style 5

Stainless Steel

[washdown rated; direct food contact]

- Continuous weld inside and outside

- Grind and polish exterior welds

- Washdown stainless steel bearings

- Epoxy painted NEMA-4X motor & gearbox

- Stainless steel loadcell

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.