Conveyor Scales

Accuracy + Repeatability = Piece of Mind

Conveyor Scales Videos

Avoid annoying ads by watching videos here. ↓

Conveyor Scales Videos

2:07

1:55

2:31

3:52

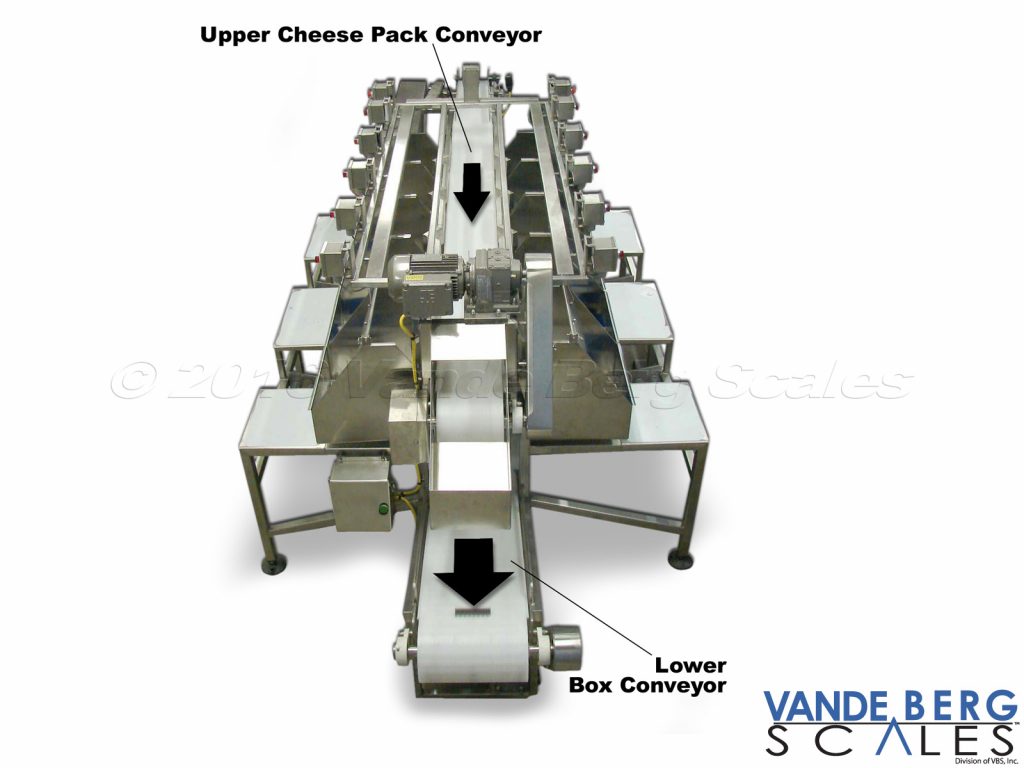

Applications

- Direct Food Contact (meat is our specialty)

- Obtaining box or bag weights

- Packaged dry foods/goods

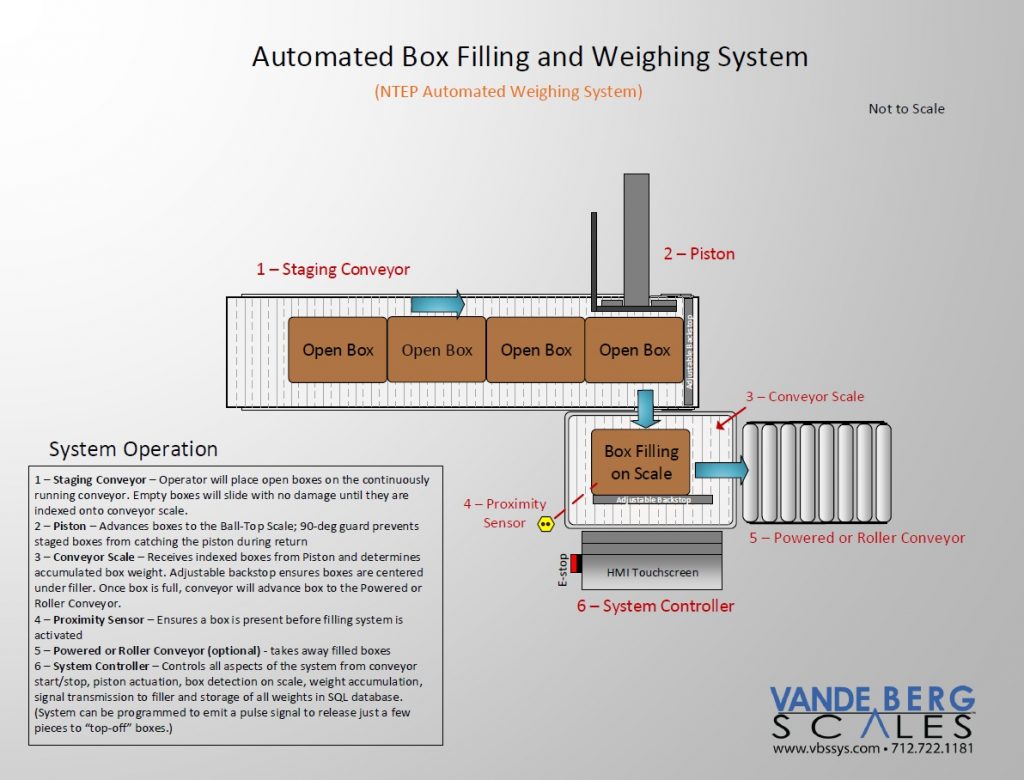

- NTEP weight verification

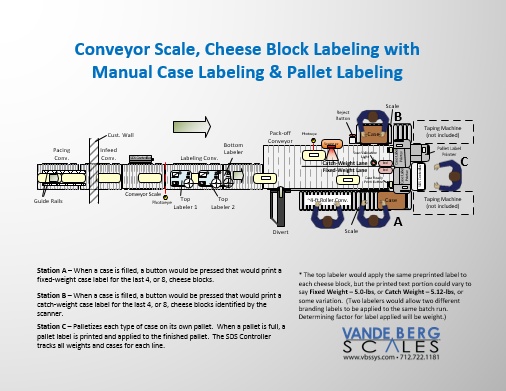

- Variable weight labeling

- Shipping

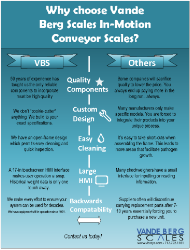

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

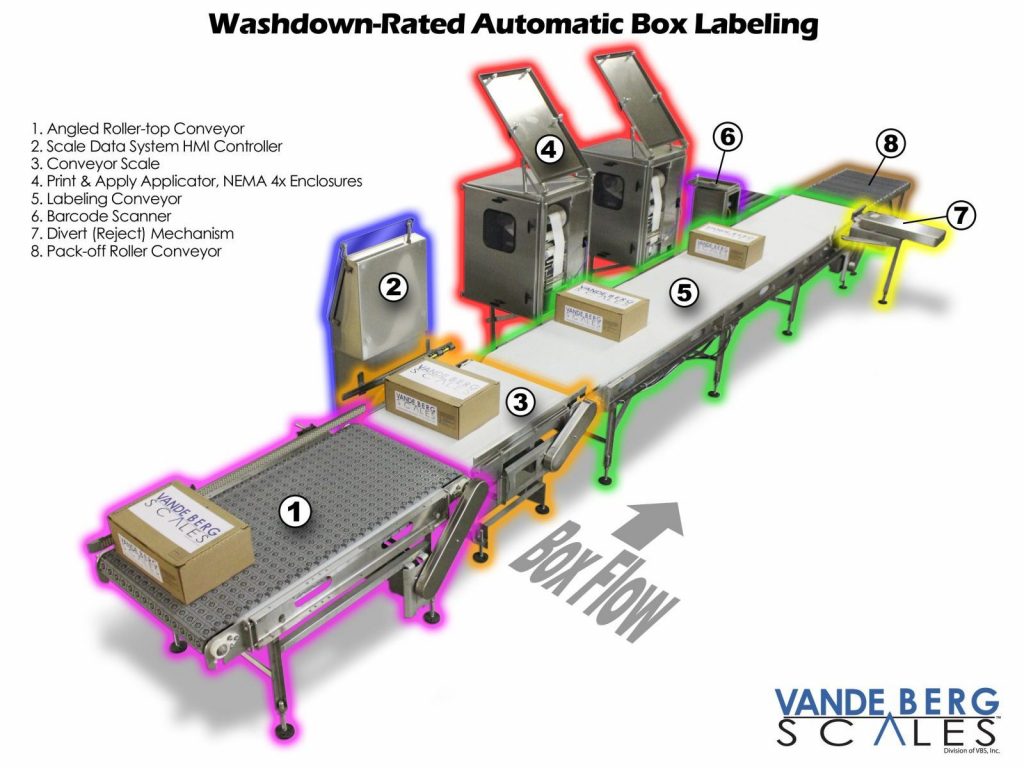

Our NTEP Certified Inline Conveyor Scales offer incredible in-motion weighing accuracy with high speed capabilities. We offer complete customization to ensure the scale fits within your existing processes and meets your exact needs.

Features & Benefits:

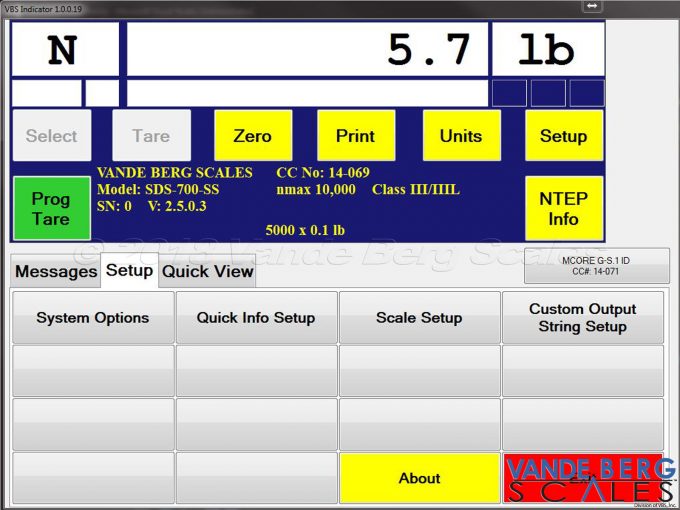

- Industrial controller samples weight at 60-80 samples/second for efficient weighing

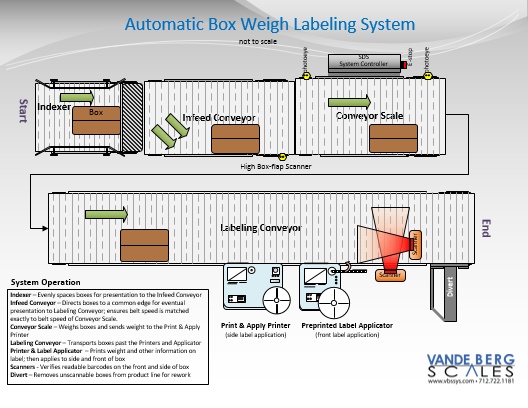

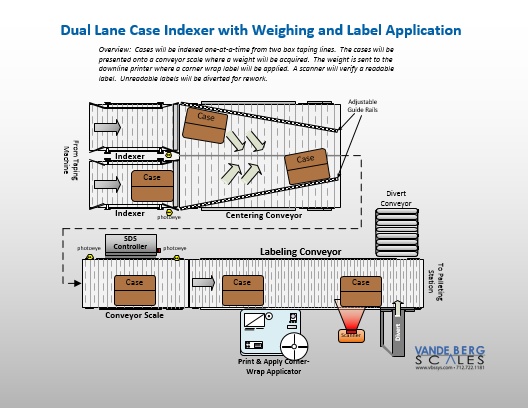

- Easy interfacing with other systems such as sorters, classifiers, automatic box weigh labeling, manual box labeling and more

- Single load cell design simplifies calibration maintenance and operation

- Smooth belt driven design ensures minimal vibration during weighments

- Safety stops help protect load cells from abusive treatment

Conveyor Scale Features:

NTEP Capacity x Resolution (Standard)

200 lb x 0.1 lb

100 lb x 0.05 lb

40 lb x 0.02 lb

20 lb x 0.01 lb

10 lb x 0.005 lb

NTEP Capacity x Resolution (Metric)

100 kg x 0.05 kg

40 kg x 0.02 kg

20 kg x 0.01 kg

10 kg x 0.005 kg

4 kg x 0.002 kg

Optional Features

- VFD to change conveyor speeds

- Stainless steel construction for washdown and food-grade environments

- Large 17-inch touchscreen HMI for ease of operator viewing and interface

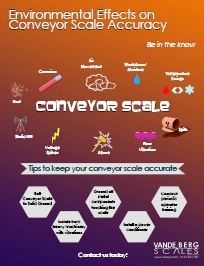

- Draft shield protects scale from environment triggered weighing errors

FAQ

A conveyor scale simply acquires the weight and sends it out.

A checkweigher will acquire the weight, compare the weight against an upper and lower limit, and then take an action. Just a few examples of actions are illuminate a light, stop a conveyor or divert the product off the line for rework (most popular).

No. Stopping the conveyor for each product would significantly increase component wear & tear, and reduce the throughput.

Even while the belts is moving our NTEP certified scale and algorithm will accurately determine the weight of the product.

NTEP is required when you are selling your product based on its weight. Therefore all food processing facilities require an NTEP inline conveyor scale in their facility when capturing product weight (which will be sold). NTEP is also required when transmitting a weight for creating a shipping label.

Yes. We offer RS-232 (serial) and Ethernet TCP/IP communication as standard. (Ethernet IP option is also available if you prefer the Allen Bradley communication protocol.)

Innovative Scale Design Elements

Single drive design virtually eliminates harmonics that can result when you have dual drives (one on each conveyor end). Harmonics often develop when motor speeds are not precisely matched. The result is internal scale movements that can significantly affect weighing accuracy.

It took years to figure out, but we came up with a single load cell design. The result is a scale that is more reliable, and less cost!

The reduced-cost part is obvious, but what about the reliability? Most scales have 4 load cells (one on each corner), so when one load cell fails, the entire scale is out of commission. Having a single load cell design significantly reduces the chances of overall load cell failure.

Since we only have one load cell, we reduce the cost by eliminating the junction box.

Moment forces need to be considered with a single load cell design. VBS has engineered a unique multi-angled bracing that consistently transfers weight to the middle, where the load cell is located.

Conveyor Scale Construction Styles

(adder for NTEP Certification)

Style 1

Aluminum

[Light-duty applications bolted; heavy-duty applications welded]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Brake parts are stainless steel

- non-washdown painted motors & bearings

- Aluminum loadcell

Style 2

Stainless Steel

[non-washdown; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- non-washdown painted motors & bearings

- Aluminum loadcell

Style 3

Stainless Steel

[washdown rated; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

- Aluminum loadcell

Style 4

Stainless Steel

[washdown rated; non-food grade]

- Continuous weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

- Aluminum loadcell

Style 5

Stainless Steel

[washdown rated; direct food contact]

- Continuous weld inside and outside

- Grind and polish exterior welds

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

- stainless steel loadcell

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.