Manual Box/Case Labeler

Amazing Box Label Flexibility

Manual Box Labeling Videos

Avoid annoying ads by watching videos here. ↓

Manual Box Labeling Videos

1:51

4:36

3:22

2:08

5:57

Additional Features & Benefits

- Software permits virtually unlimited number of definable products

- Automatic or manual weigh print functions for your case

- Interfaceable to network servers for supervisor oversight

- On-screen reprint capabilities

- Can fuction as a checkweigher to identify missing product

- "Mistake label" button easily removes duplicate labels from the current batch

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

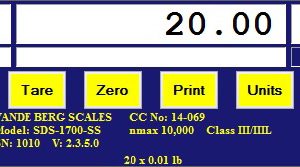

This Manual Box/Case Weigh Labeling System combines several elements (scale, controller, printer and HMI interface) onto a frame that enables either mobile or stationary use. Easy-to-use interface makes weigh labeling a breeze!

Features & Benefits:

- Allows you to accurately and efficiently identify, weigh and label your product

- Includes Scale, HMI Touchscreen, Embedded Controller, Software and Printer for all-in-one operation

- Complies with NTEP and Legal-for-Trade use

- Easy to use touchscreen interface minimizes training time and clutter

- On-screen hot-keys permit quick product selection for faster label printing

- NEMA-4X units can withstand tough washdown environments

Manual Box Labeler Features:

NTEP Capacity x Resolution (Standard)

200 lb x 0.05 lb

100 lb x 0.02 lb

40 lb x 0.01 lb

20 lb x 0.005 lb

FAQ

Yes – It has all the components needed to start making labels and applying them immediately. It is a completely system. Just plug it in!

Yes. We can fabricate the components in any arrangement you need. We will ensure it maximizes your product throughput for your line.

This system is designed to operate independently of a network, but you can connect to the system to see the MS SQL database being populated in real time.

Yes. We do have an option allowing you to print a pallet manifest. See Pallet Manifest Example

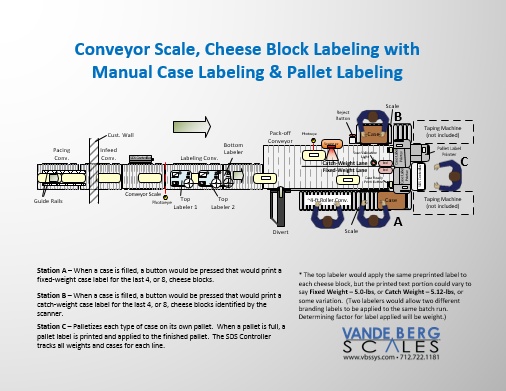

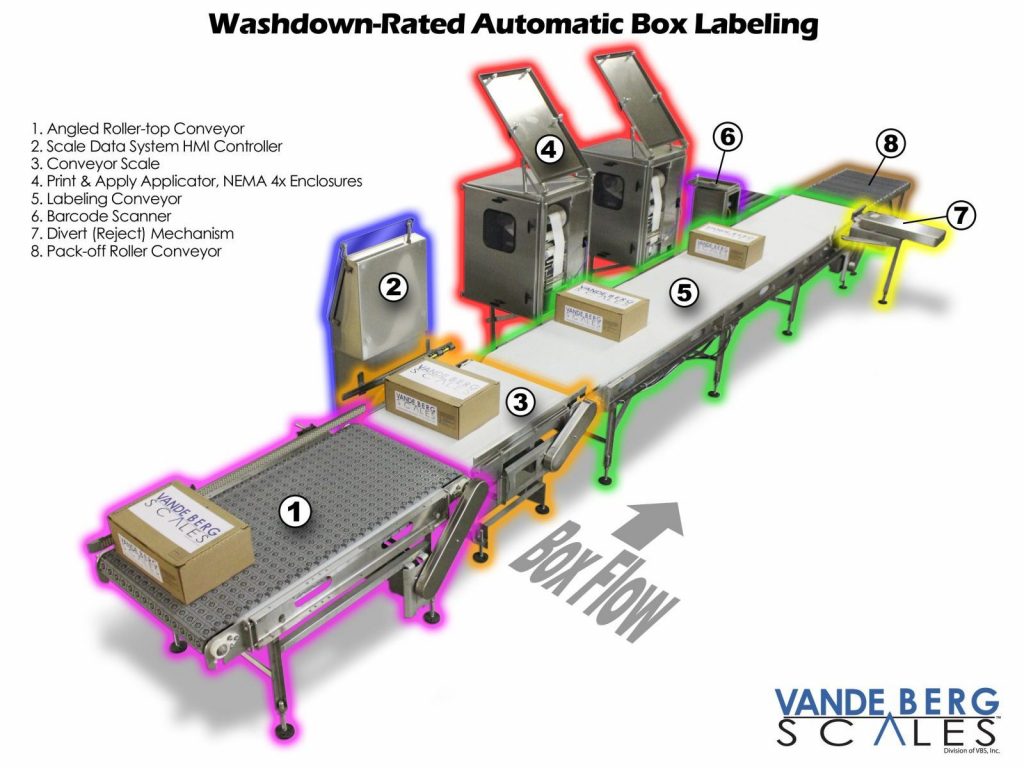

Primary Components in Manual Case Labeling

- Static Scale to weigh boxes

- System Controller to calculate net weight, format label, and send information to printer

- Touchscreen HMI to permit user to easily interface with the system

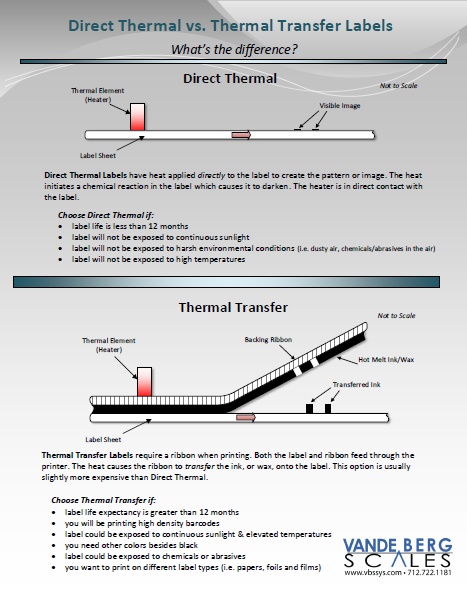

- Printer to print labels efficiently and quickly

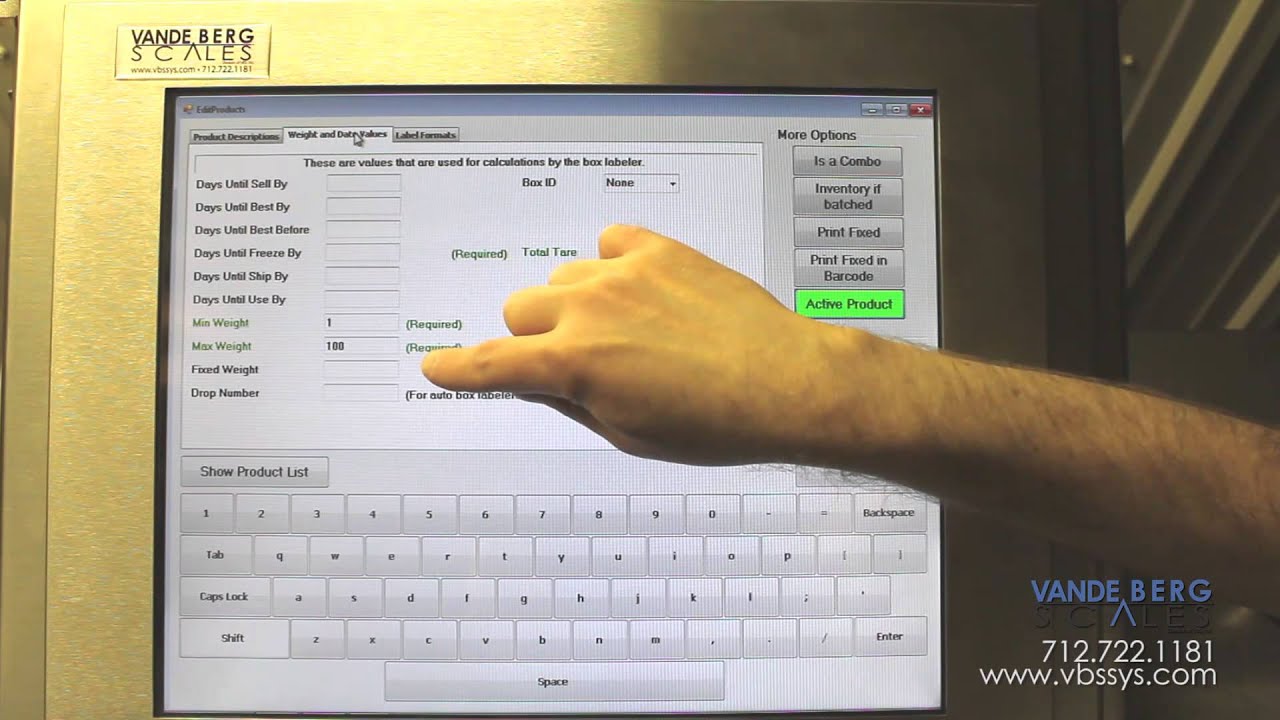

Box/Case Labeling Program & Features

How it works!

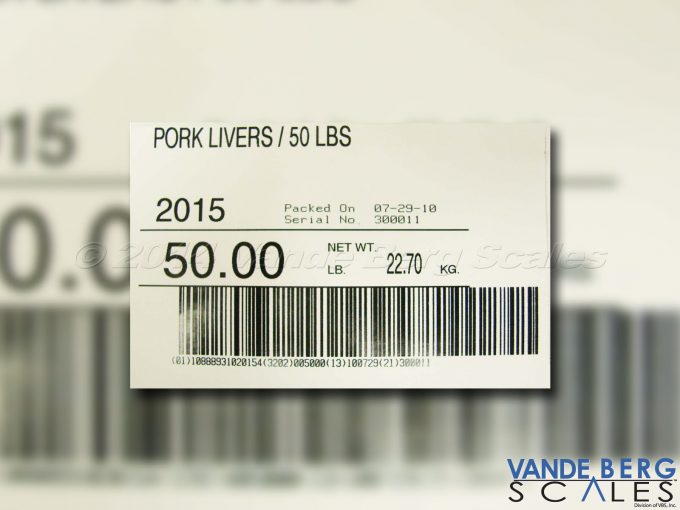

- User identifies a product to be weighed by selecting it from a hot-key list, product list, or scanning a pre-applied label to get the product ID

- The case/box is placed on a static scale

- If the net weight for the case/box is within the bounds of the minimum and maximum for the product, the process continues

- The embedded controller will accept the net weight, retrieve additional product data, format and send the label to the printer for label generation

Thoughtful Programming Features

- VBS created the software therefore you deal directly with the people that configure and program the applications. This assures you the product fits your exact needs.

- All transactions are stored in a MS SQL database

- Password protected when and how you need it

- Includes Label Designer Software (see directly below) that allows you to design your own label formats and transfer (via USB) to floor unit(s)

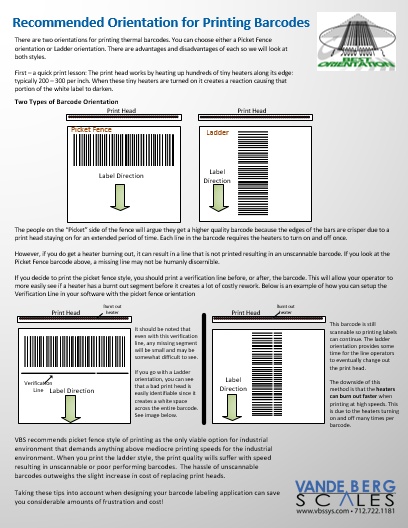

Label Designer Software (Included)

Supports most industry standard barcodes such as:

- 2D Barcodes (call us for format type)

- Code 39: Variable length, alpha-numeric

- UPC A: 12 digits, numeric only

- UPC E: 7 digits, numeric only

- I-2 of 5: Variable length, numeric only

- Code 128 Type A & B: Variable length, alpha-numeric

- Code 128 Type C: Variable length, numeric only, number

How do I create a label & print it?

Simply create the label on a Windows® desktop computer, transfer to a USB storage device and upload to our Scale Data System (SDS). The SDS Controller can simultaneously store several labels for quick selection based on product. You can also test print a label on any compatible label printer to preview before transferring to the SDS.

Features & Benefits:

- On-screen label format display (WYSIWYG)

- User-defined product labels limited only to disk space

- Product specific or universal label formatting

- Compatible with Windows® XP, 7 & 10 operating system

- Product definable fields

- Import company-specific or USDA bitmaps

- Create line, box and circle shapes

- Capable of batch printing fixed weight labels

SDS Controller which accepts the label format for eventual label printing on a box or package. Learn more about the SDS Controller.

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.