Box & Package Conveyors

Significantly reduce manual box handling

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

Reduce manual box/case handling thereby saving labor while improving throughput to greatly enhancing your processing efficiency.

Features & Benefits:

- Save significant labor in handling boxes

- Mechanical design allows easy lengthening to allow expandability

- Sturdy design ensures long life

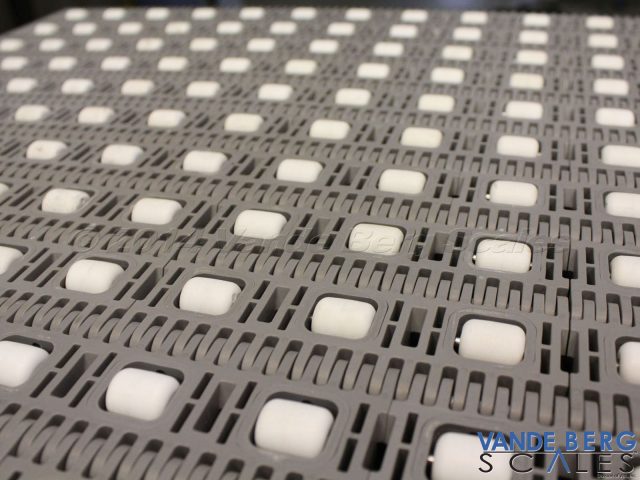

- Modular plastic belt assures conveyors are easy to align and maintain

- Motors and gearboxes are industry standard types allowing multiple vendor utilization for maintenance

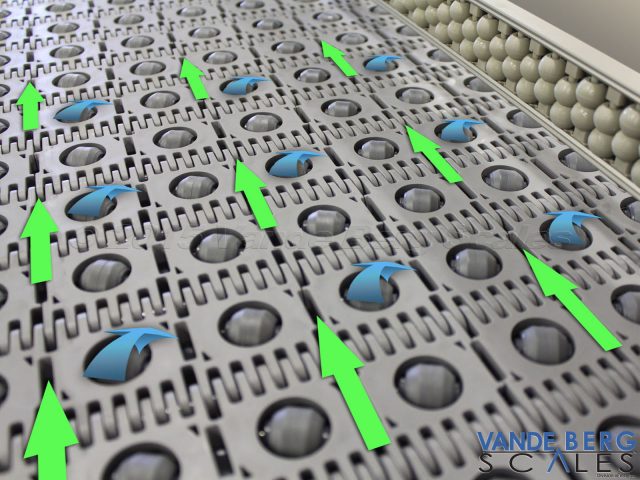

- Innovative belt designs can automatically reposition product optimizing automation

Conveyor Design Features:

5 Areas that Steal Productivity

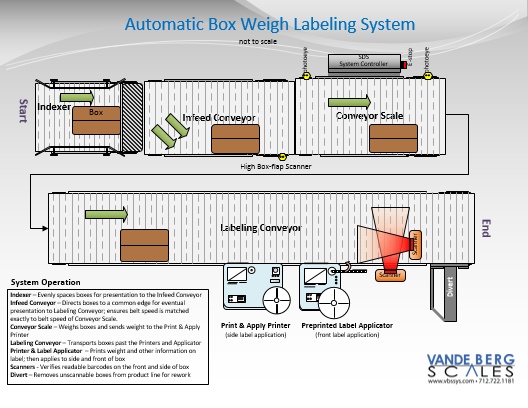

- “Log” jams where products run into each other requiring a person to manual separate the boxes

- Positioning that require manual turning so a common side presents for labeling or scanning

- Improperly spaced boxes resulting in a label not applied correctly or two boxes present on a scale simultaneously

- Boxes not aligned properly resulting in poor label application or misread barcodes

- Out-of-tolerance boxes/cases that stay in the production line resulting in frustrated customers

Conveyor Construction Styles

Style 1

Aluminum

[Light-duty applications bolted; heavy-duty applications welded]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Brake parts are stainless steel

- non-washdown painted motors & bearings

Style 2

Stainless Steel

[non-washdown; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- non-washdown painted motors & bearings

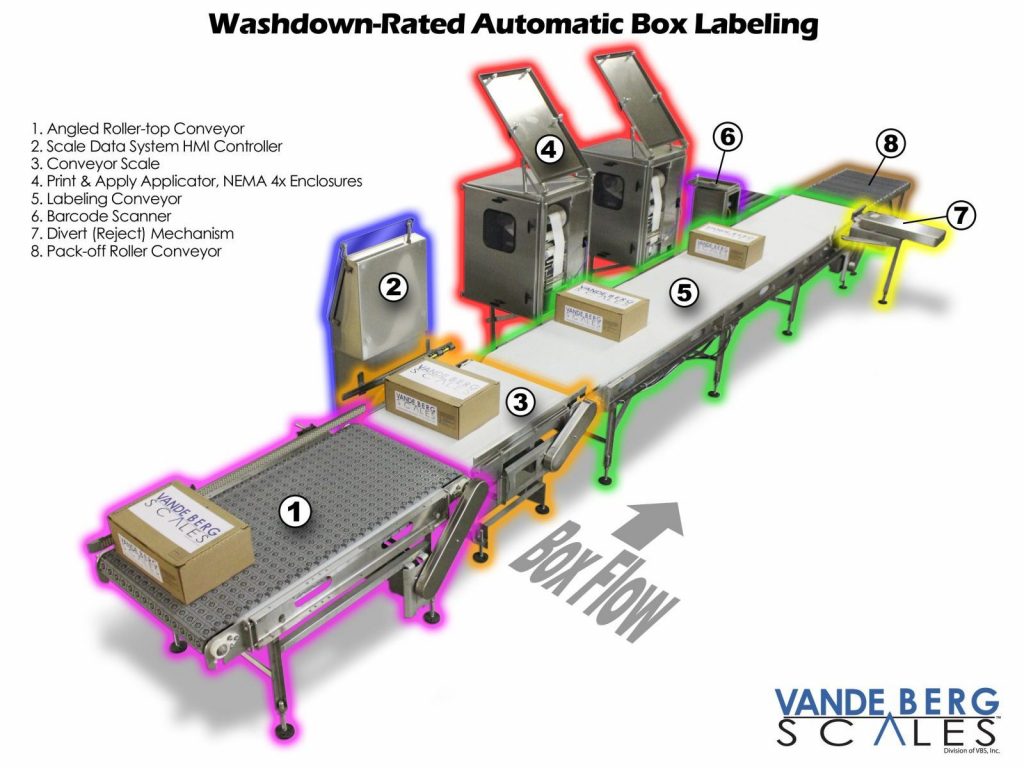

Style 3

Stainless Steel

[washdown rated; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Style 4

Stainless Steel

[washdown rated; non-food grade]

- Continuous weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.