Stainless Steel Food-Grade Conveyors

Minimize Conveyor Cleaning Time

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

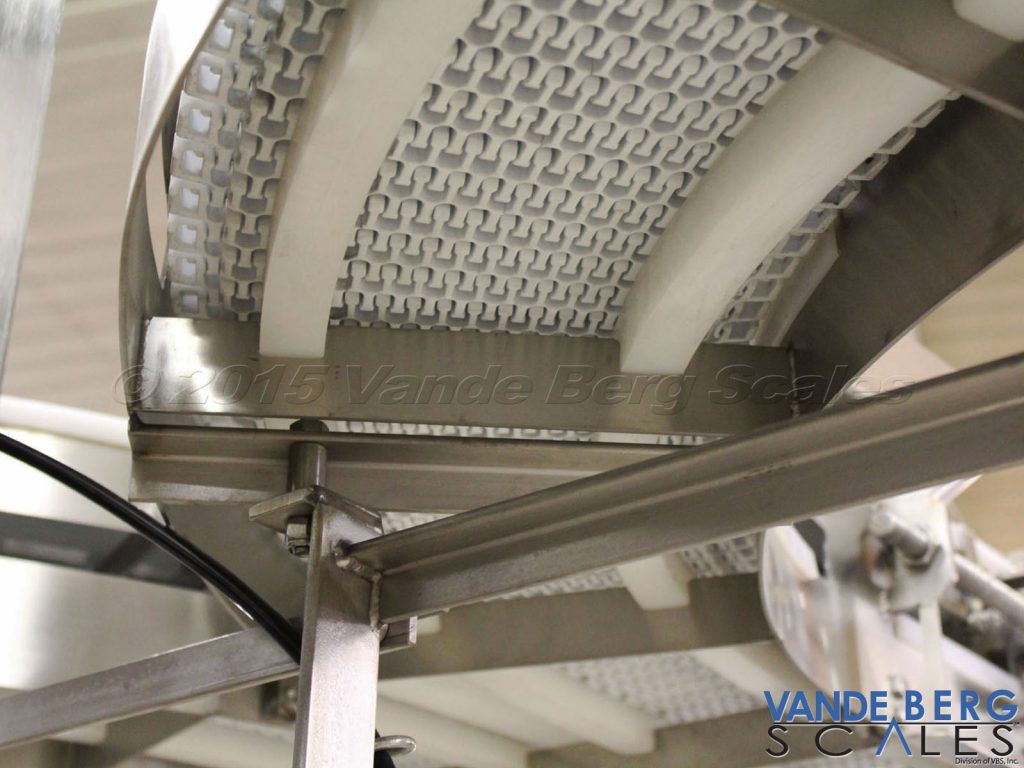

Designed for direct food contact, our Food-Grade Conveyors are built to handle tough washdown environments. Stainless steel (SS) and Ultra-high molecular weight UHMW construction materials are USDA approved.

Features & Benefits:

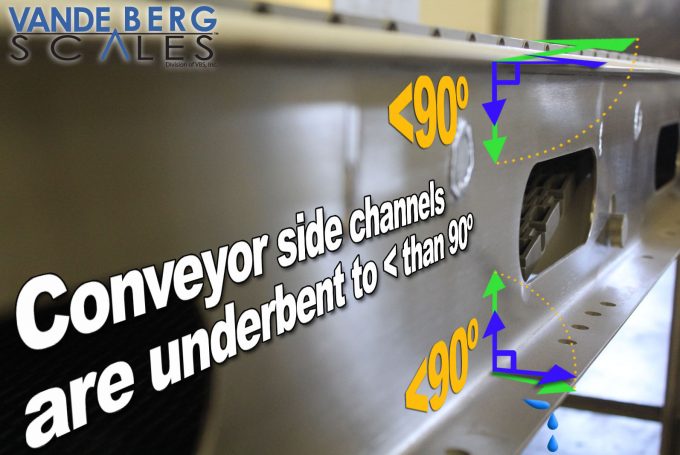

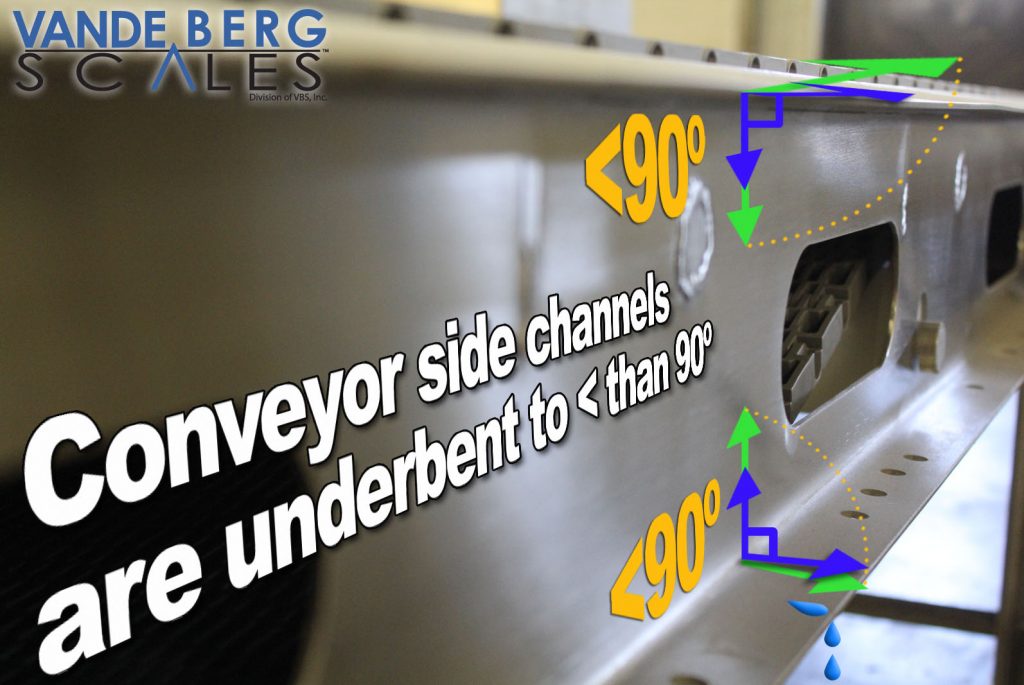

- Designed to minimize standing water on stainless steel parts

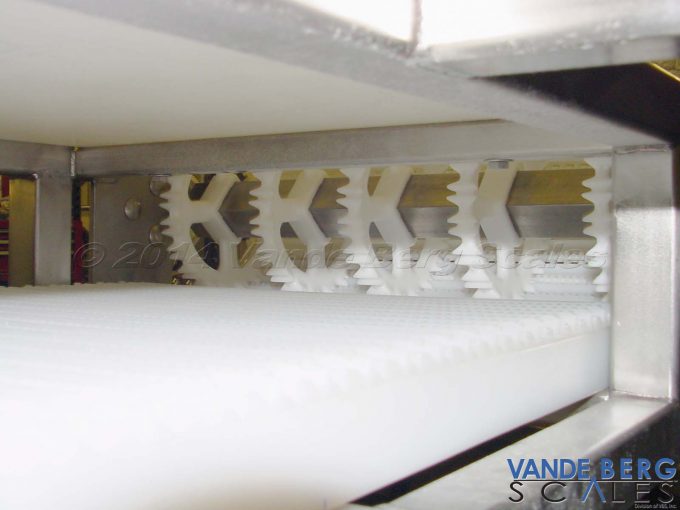

- Reduce cleaning times with our open frame design and easy access to direct contact surfaces

- Solid construction ensures decades of use

- Sanitary design reduces pathogen and bacteria build-up

- Modular 10-ft sections permit 40-ft or longer of continuous conveyor (dependent on conveyor width)

- Can be cleaned while in-motion with optional features

Conveyor Design Features:

Innovative Food-Grade Conveyor Design Features

Sanitary Conveyor Construction Styles

Style 1

Aluminum

[Light-duty applications bolted; heavy-duty applications welded]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Brake parts are stainless steel

- non-washdown painted motors & bearings

Style 2

Stainless Steel

[non-washdown; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- non-washdown painted motors & bearings

Style 3

Stainless Steel

[washdown rated; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Style 4

Stainless Steel

[washdown rated; non-food grade]

- Continuous weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Style 5

Stainless Steel

[washdown rated; direct food contact]

- Continuous weld inside and outside

- Grind and polish exterior welds

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.