Washdown Printer Applicator

No more soggy printer components

Additional Features:

- Ethernet TCP/IP Communication

- CAN Open Controller

- Fool-proof hand crank for adjusting the height

- Sealed motors and bearings

- Fully backup all setting/info on a USB stick

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

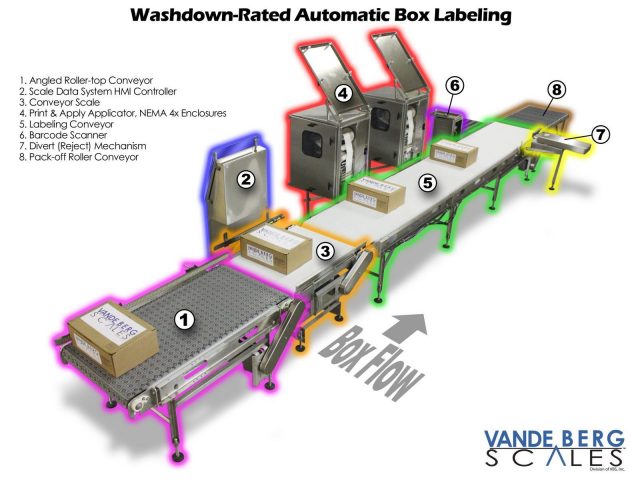

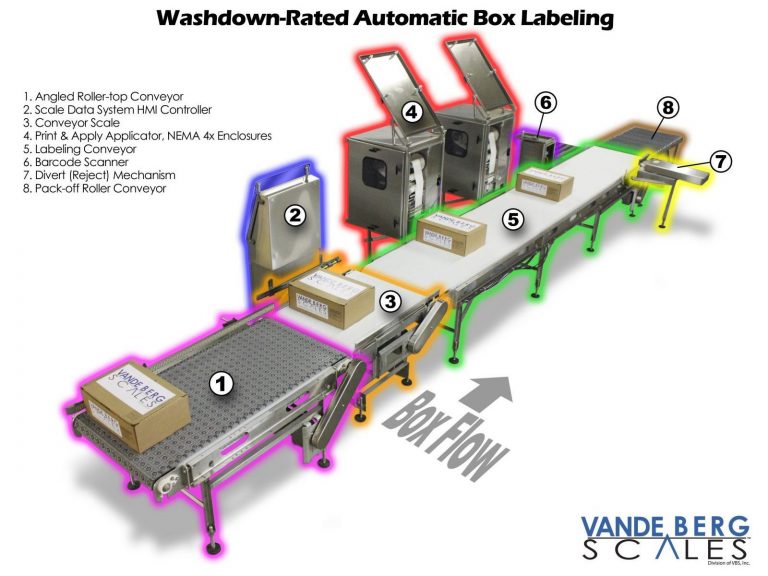

Introducing a washdown compatible Printer/Applicator. Simply close the doors to keep all components dry before washdown. Printers are bolted to the conveyor thereby virtually eliminating realignment hassles during startup.

Features & Benefits:

- NEMA-4X enclosure keeps printer components dry during washdown

- Simplified engineering improves reliability

- Operator friendly Windows®-based controller

- Inexpensive parts replacement

- Printer is secured to the conveyor so no setup time is needed after washdown

Washdown Printer Enclosure Features:

FAQ

No. The printer enclosure is bolted to the frame so there is no need to readjust the printer to ensure it is aligned.

Our enclosures are made with 3-side access so you have unrestricted access to virtually all printer components.

Yes – We can custom design a washdown-rated enclosure for your printer/applicator.

Uses an A-Class Mark II Datamax Print Engine

- Choose either direct-thermal or thermal-transfer

- 4.16-in maximum print width (6-in optional)

- 10-inch/sec print speed (application dependent)

- 203 dpi (8 dots/mm) resolution (ask for higher resolutions)

- Serial RS-232, Parallel Bi-Directional, Ethernet Wired LAN Communication

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.