Box Indexing Conveyor

Stop Manually Spacing Boxes

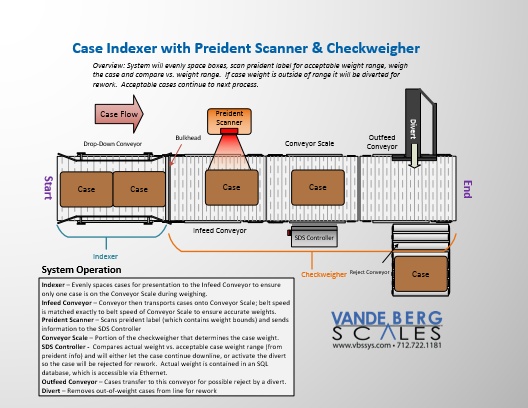

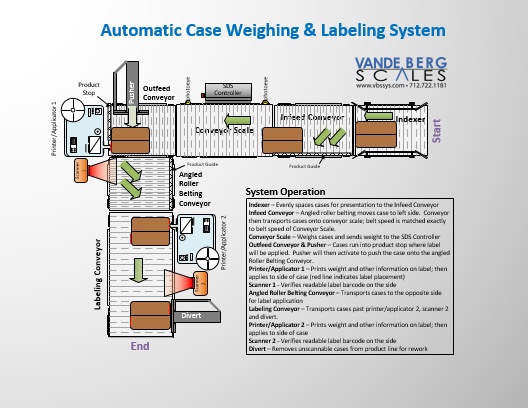

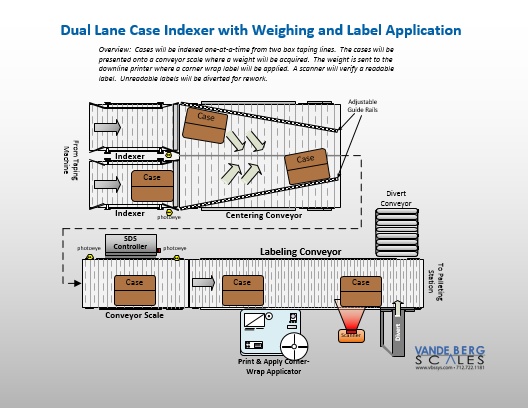

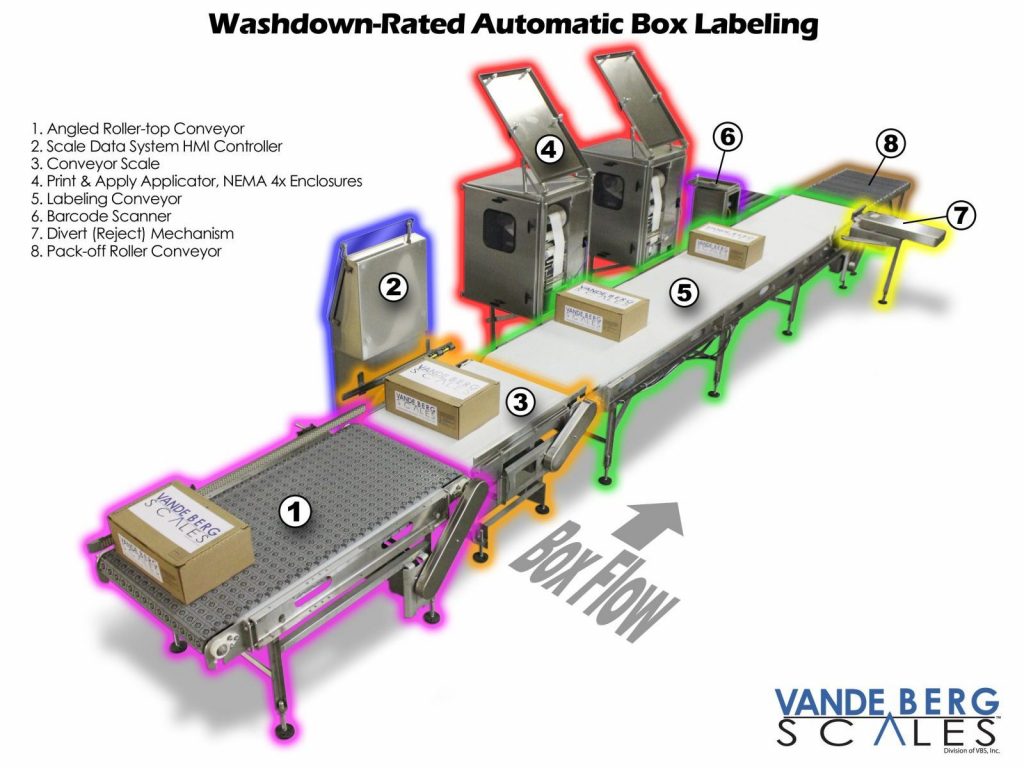

- In-motion weighing scales

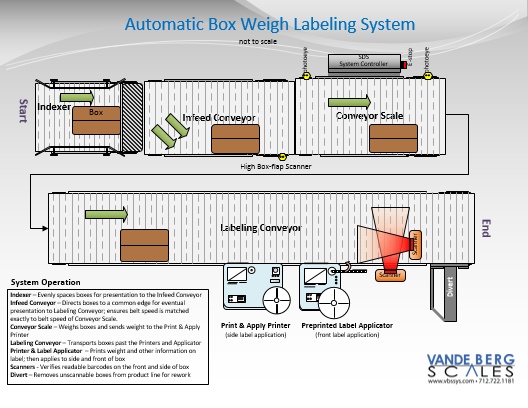

- Automatic labeling stations

- Scanning stations

- Palletizing stations

- Sorting systems

Indexing conveyors (Indexers) create consistent spacing of boxes/cases thereby virtually eliminating traffic jams. Indexers also permit product to be properly presented so labeling and in-motion weighing can occur without hassle.

Features & Benefits:

- Creates a consistent start-of-box to start-of box spacing

- Compliments existing equipment with standalone control capability

- Enables down-line printers, checkweighers, conveyor scales and scanners to function within specification

- Easy adjustment of spacing between products

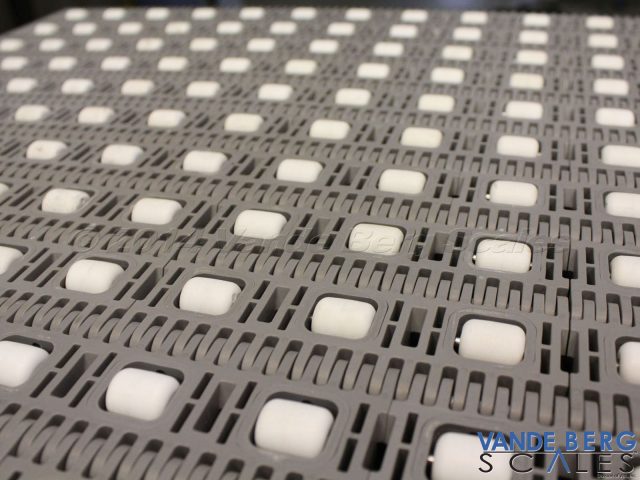

- Roller belting permits product to roll on belt while waiting for advancement, which reduces friction wear of product

Indexer Design Features:

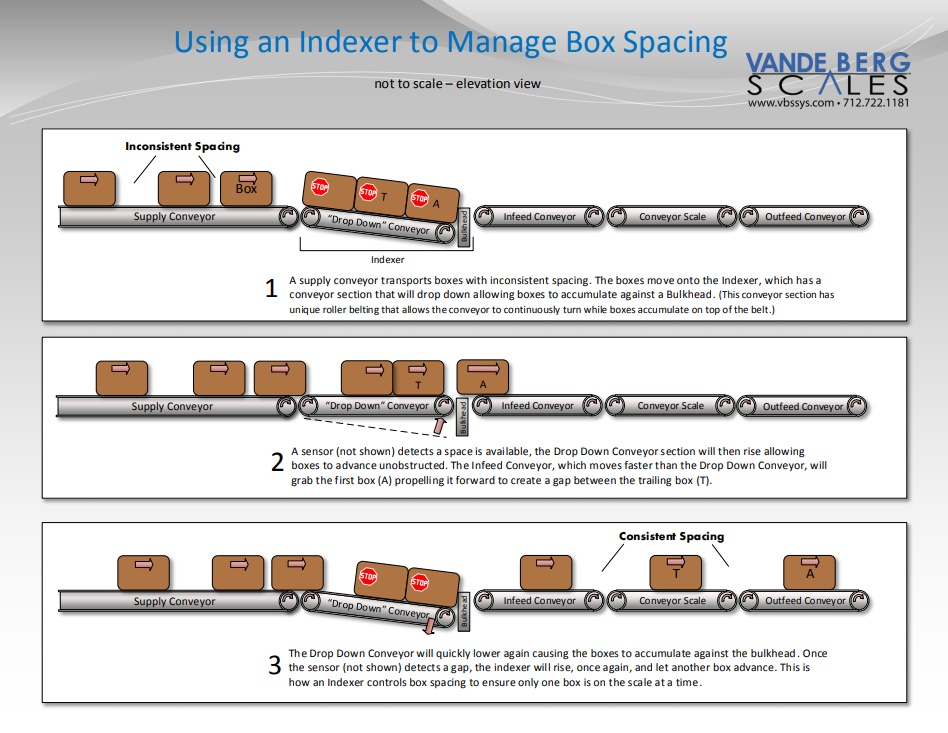

How a Box Indexing Conveyor Works:

An indexing conveyor will automatically release each box one at a time at a settable rate by dropping down the tail of the entry conveyor so that a box to be held back will come to a stop against a conveyor bulkhead until the entry conveyor is lifted via automatic control. A speed up roller with then rapidly propel the box away from the following box allowing a gap to be sensed by a photo eye. The photo eye coupled with the conveyor speed change is employed to ensure that every trailing box will be delayed to the proper box leading-edge to leading-edge frequency. The end result will be even start to start spaced boxes exiting the system.