Stainless Steel Printer Enclosures

Completely customizable!

Printer Enclosure Options:

- Top, bottom, left or right side hinges

- Key-locking door handle

- Plexiglas window in door

- Internal heater to keep components functioning properly

- Attach to a stand or a post to elevate to working height

- External mounting tabs

- Watertight Communications port

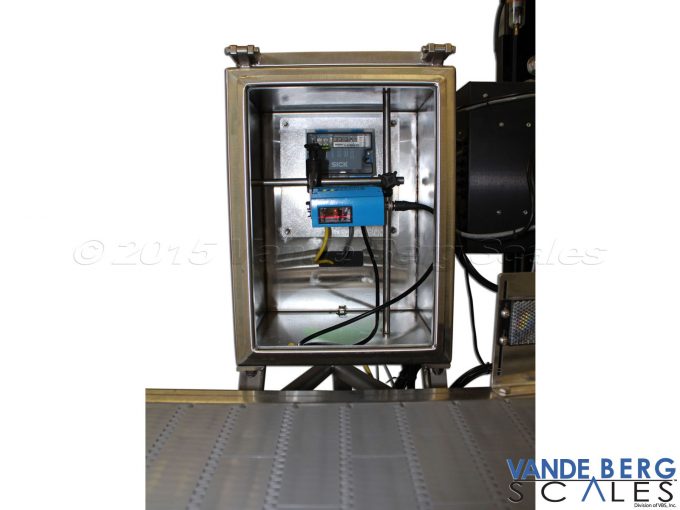

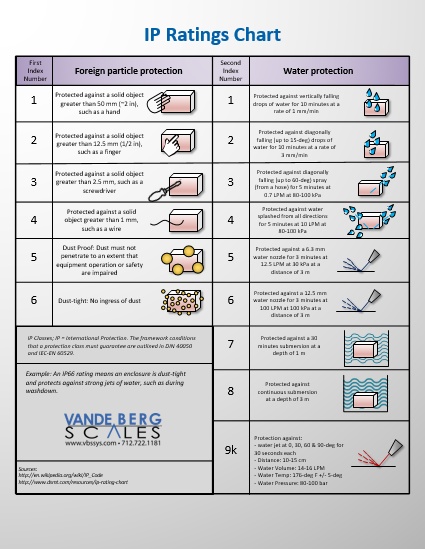

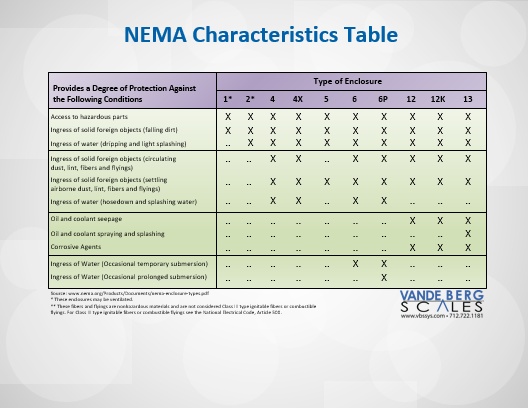

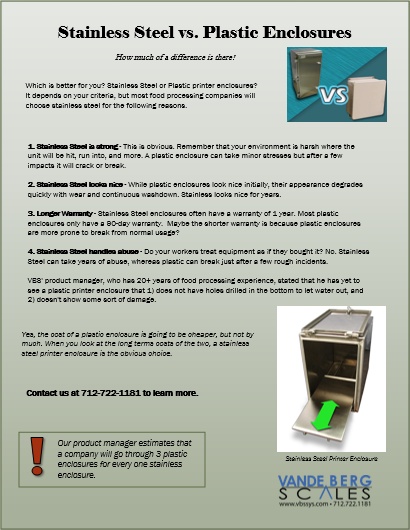

Prevent water from damaging your printers with our industrial NEMA-4X stainless steel washdown-rated enclosures. Reduce down time by keeping your electronics dry and running properly.

See our Enclosure Gallery

Features & Benefits:

- Continuous TIG welded construction of polished 14G 304 stainless steel assures robust characteristics for longevity

- Wash-down, rain gutter style door seal prevent direct spray from contacting the door

- Single ½-turn easy to operate door latch allows operators to quickly and easily open the door

- Pull out tray is designed for quick access for label roll changes and equipment access

- Top-hinged door allows door to swing nearly 270º to relieve the operator from door obstructions while in use

Washdown Enclosure Features:

FAQ

Yes. Not only can we make it any size, but we can: add as many doors as you need, shelves as you want, windows in any location and add a stand to support the enclosure.

Yes. Many industries need this and we can add an aluminum panel on any side and provide standoffs.

Yes. We design and fabricate all enclosures at our Sioux Center, IA location.

The highly loaded hinges invariably crack and break the enclosure at the attachment point. This allows the environment to penetrate the enclosure. Repetitive purchasing of lesser quality and replacement of damaged internal components often cost more than our stainless steel products. Give me a dented enclosure over a cracked enclosure any day. (See our info PDF)

All types – Zebra, Datamax, Intermec, Sato, Honeywell, Printronix and more.

7 Design Criteria for Keeping Water Out of an Enclosure

1. Sloped Top – For many food processing facilities, standing water is not welcome. Therefore, the top of the cabinet is sloped ensuring water runs off and does not pool.

2. Rain Gutter – a rain gutter prevents a high pressure water stream from achieving a “direct shot” at the door seal. The rain gutter acts as a deflector for the high pressure water stream when the door is closed.

3. Quality Door Seal – Most of our enclosures use a 1-in wide x 0.25-in thick gasket. This ensures a continuous seal even if door alignment starts to deviate over years of use. The gasket material is blended Neoprene that is mixed with EPDM and SBR. In addition, the gasket is made of a closed-cell foam that does not absorb water.

4. Multiple Locking Handles – We use multiple cam-locking handles that lock the door in place, but also pull the door towards the seal as you turn the handle. We also use several handles along the door edge to ensure positive pressure along the entire edge of the door or access panel. (Even the handle has an internal gasket.)

5. Penetrations are kept to a minimum – We weld external flanges where ever possible so components (i.e. light bars, antennas) are connected to the flange vs. securing the component directly to the enclosure, which would require drilling holes and creating a potential water entry point. Any cables are then run through the Cord/Cable Entry.

6. Well-Insulated Cord/Cable Entry – Our well protected cord/cable entry allows you the advantage of wiring your enclosure without having to cut and splice your cables. It can accommodate many industrial cables entering the same location. The cables are sandwiched between multiple layers of closed-cell foam.

7. Double-Shear Point External Hinges – External hinges allow the door to make an even seal around the entire outside edge vs. internal hinges which often have reduced seal material in the vicinity of the hinge.

Stainless Steel Enclosure Gallery - These are completely customizable!

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.