Metal Detectors with Conveyor (no longer offered)

Accurately detect metal contamination

Performance Features:

- Available in eight different standard sizes, on request available in customer-specific sizes

- High mechanical stability and high interference immunity; largely insensitive to vibration, impacts, and temperature fluctuations

- Hygienic design, easy to clean, no dirt-collecting edges

- Detects metal fragments regardless of location inside product

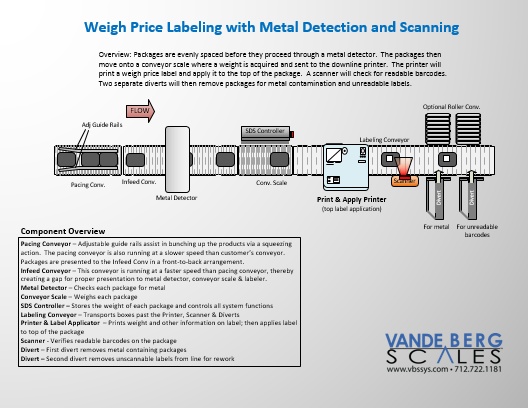

- Variable weight labeling

- Shipping

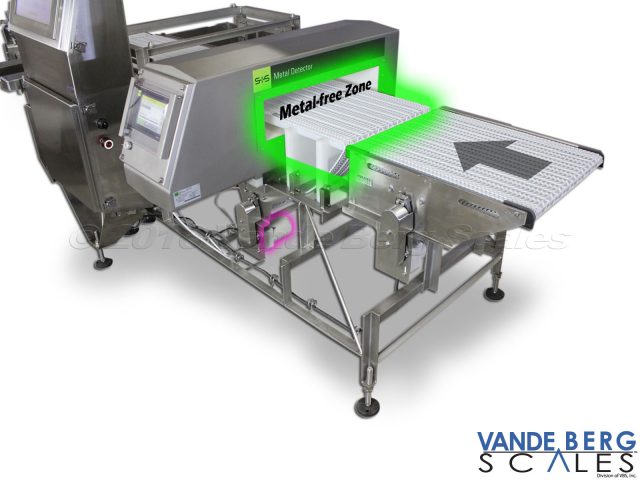

Keep your products safe with our metal detectors. Special conveyor design incorporates a metal-free zone and motor mounted away from aperture to minimize interference.

Features & Benefits:

- Can be used almost anywhere in the food processing line

- Operates over a wide range of speeds to accommodate a variety of food lines

- Long life in harsh environments, especially washdown

- In-process and end-of-line metal contaminant protection to comply with IFS, BRC, HACCP, ISO 22000 requirements, etc.

- Detects ferrous and non-ferrous metals, including stainless steel

Metal Detector Features:

Metal Detector Purchasing Considerations:

- Decide what types of metal you need to detect. There are two main categories of metal: ferrous and non-ferrous. Ferrous metals are derived from iron or contain iron. Non-ferrous metals are all others. Take a careful inventory of the types of metal in your operation that could possibly end up in your products.

- What sizes of metal contaminants do you need to screen for? You need to be practical and realistic with this question because if you specify too much sensitivity, you will get too many false alarms and vice versa.

- Know the operating environment and the product characteristics – The operating environment includes the temperature and whether water, dust, or chemicals could come in contact with your metal detector, as well as possible electrical fields. Additionally, is the product fresh or frozen, packaged or exposed, scanned individually or in a case? All of these factors will go into the design of a metal detector that will fit your needs the best.

- Reject System considerations – Most commonly, a pusher or an air blast is used to divert products where metal has been detected. However, you could save space by having the conveyor belt stopped and a warning light activated. Additionally, an optional Lockable Collecting Container prevents unauthorized employees from gaining access to rejected product.

Additional Videos

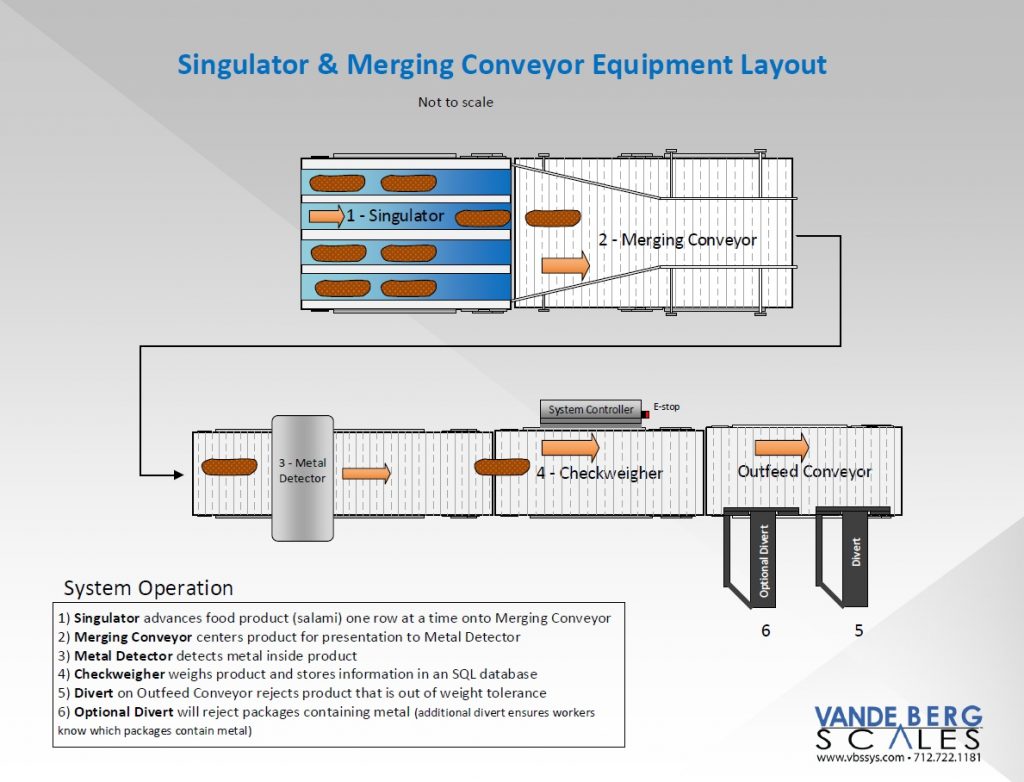

Singulator, Checkweigher & Metal Detector System (3 in 1)

Metal Detector & Checkweigher with Dual Diverts

Conveyor Construction Styles

Style 1

Aluminum

[Light-duty applications bolted; heavy-duty applications welded]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Brake parts are stainless steel

- non-washdown painted motors & bearings

Style 2

Stainless Steel

[non-washdown; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- non-washdown painted motors & bearings

Style 3

Stainless Steel

[washdown rated; non-food grade]

- Stitch weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Style 4

Stainless Steel

[washdown rated; non-food grade]

- Continuous weld on one side

- Debur and clean discoloration on welds - no grinding

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Style 5

Stainless Steel

[washdown rated; direct food contact]

- Continuous weld inside and outside

- Grind and polish exterior welds

- Washdown stainless steel bearings

- epoxy painted NEMA-4X motor & gearbox

Downloadable PDF Resources

Need a Quote in a Hurry?

Download our questionnaire and fill it out to get a quote.