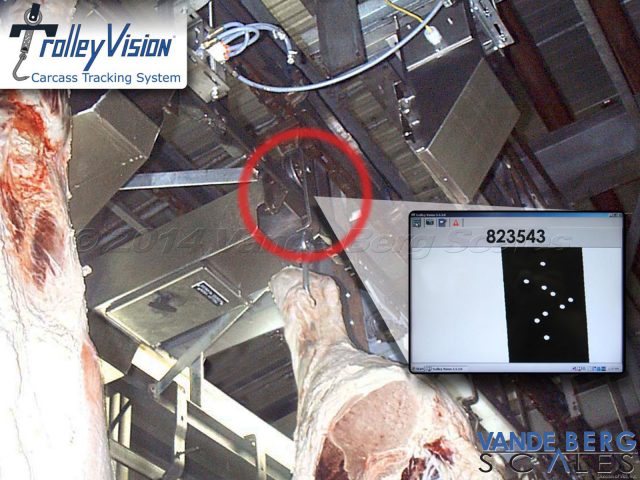

Trolley Vision® Carcass Tracking

Stamp a virtual license plate on each carcass

How does it work?

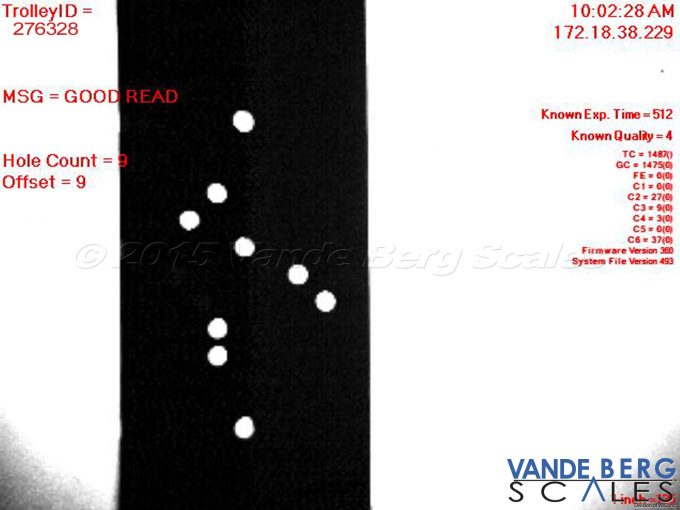

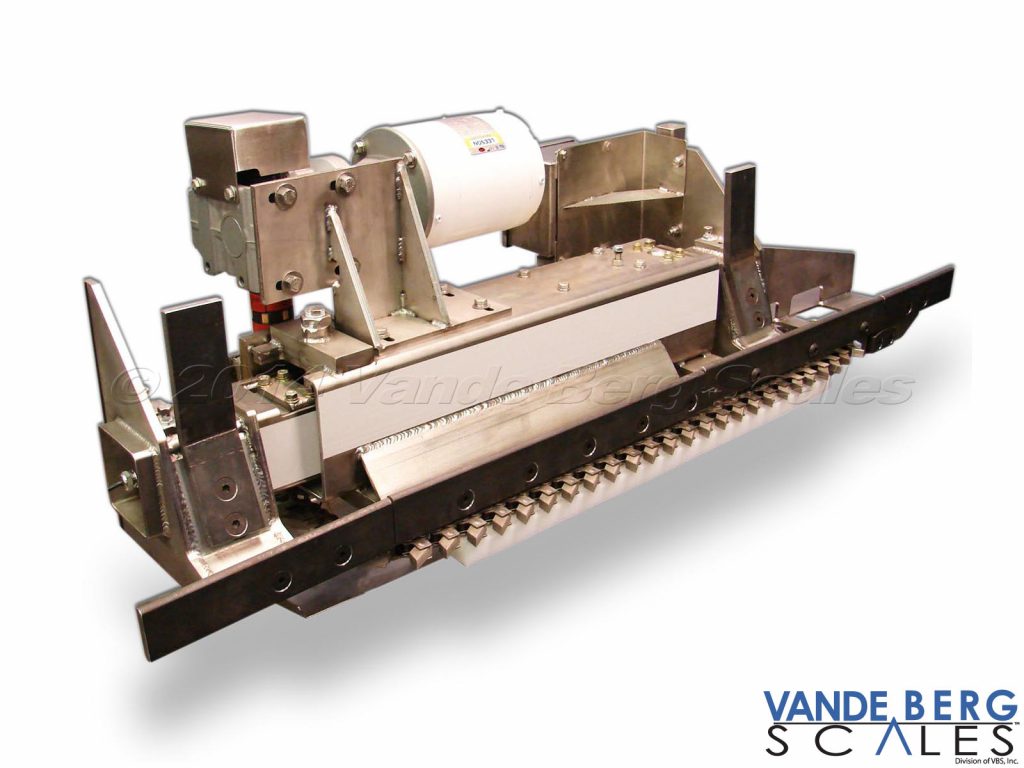

Each trolley strap has a unique set of holes. As the strap passes by a camera with back-light, a digital picture is analyzed by the firmware. The pattern is immediately recognized and the unique identifying tracking number is sent to interfaced electronic equipment. The data is stored in an SQL database for local or remote retrieval allowing full diagnostic capability.

No parts pricing sucker punches – VBS uses standard, industry-available components that are easily attainable from multiple vendors, in the design and construction of our equipment assuring our customer economical, simplified, fast and efficient maintainability.

Trolley Vision® is the industry leading carcass tracking system. It is designed for harsh environments and achieves unequaled read rates with proper maintenance.

Features & Benefits:

- Guaranteed read rates exceeding 99.5% with proper maintenance. (In fact, our largest customer tells us that 99.97% is routine.)

- Simple to operate and can be remotely monitored

- Each trolley is unique with a possible choice of over 40,353,607 identities thereby ensuring no duplicates

- vacuum/blower ensures debris build-up does not plug identification holes over time

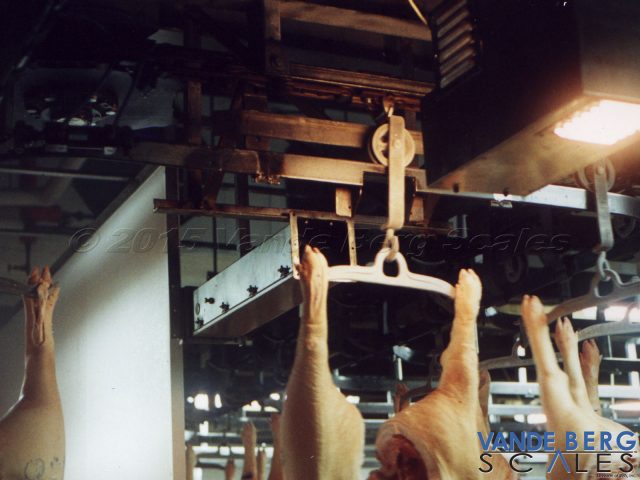

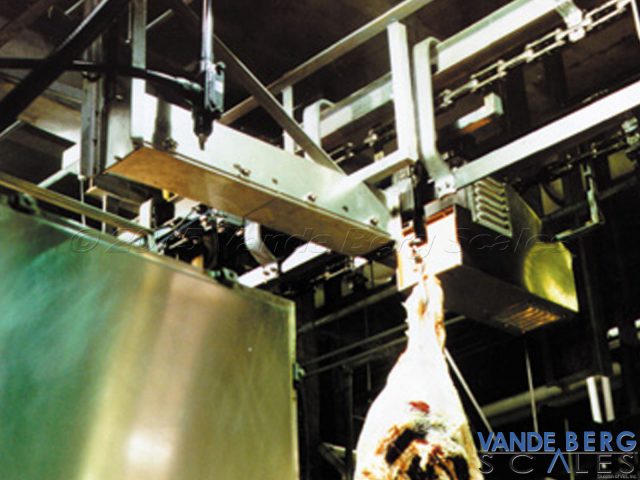

- Built to handle tough packing house/harvesting conditions thereby ensuring reliability

Trolley Vision® Features:

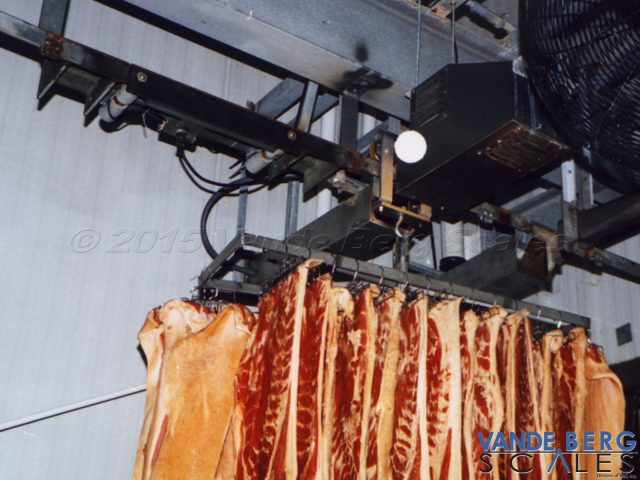

Trolley Vision® Application Images:

Applications

- Specific carcass yield performance

- Grade tracking

- Kill-floor yield tracking

- Specific supplier yield performance

- Enhanced traceability

- Smokehouse yield tracking

- Cooler shrink analysis

- Automatic gainer rejection

- Specie yield comparison

- Enhanced country of origin (COOL) tracking