Static Multi-cell Monorail Scale

Reliability & Accuracy

Additional Features & Benefits

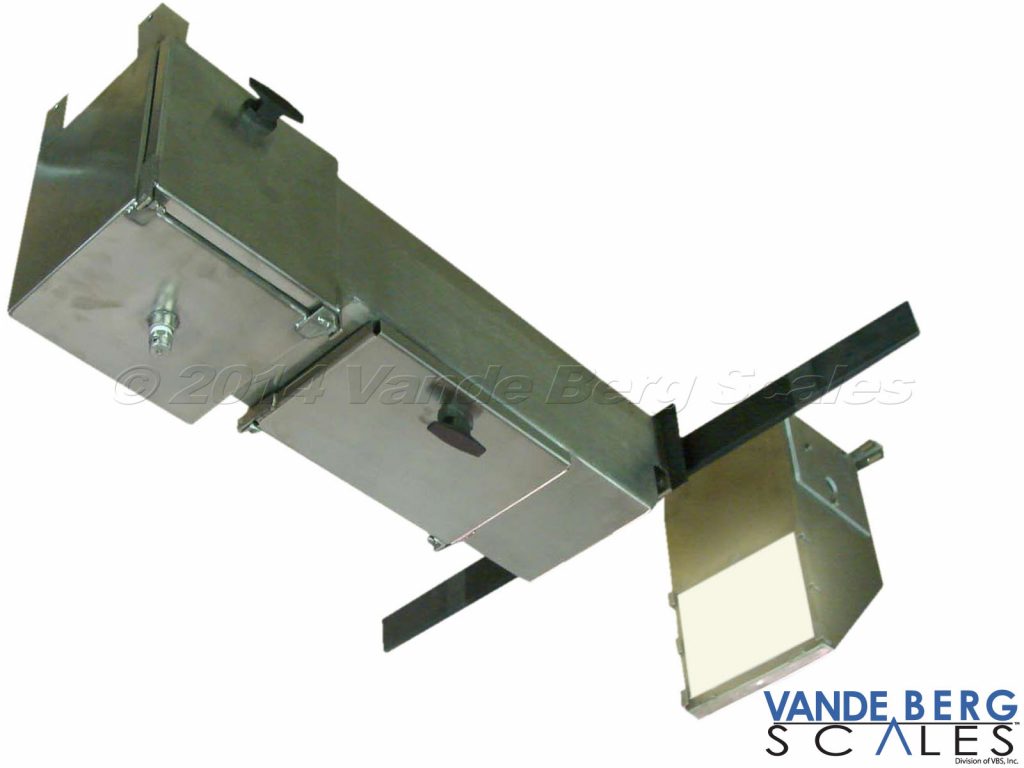

- Continuously welded stainless steel structure assures proper sanitary conditions

- 12-48-inch live rail section allows a custom fit for you facility

- Massively rigid frame structure results in reduced weighing errors due to flexing

- Rugged stainless steel sealed load cells are design for harsh washdown environments

How is this monorail installed?

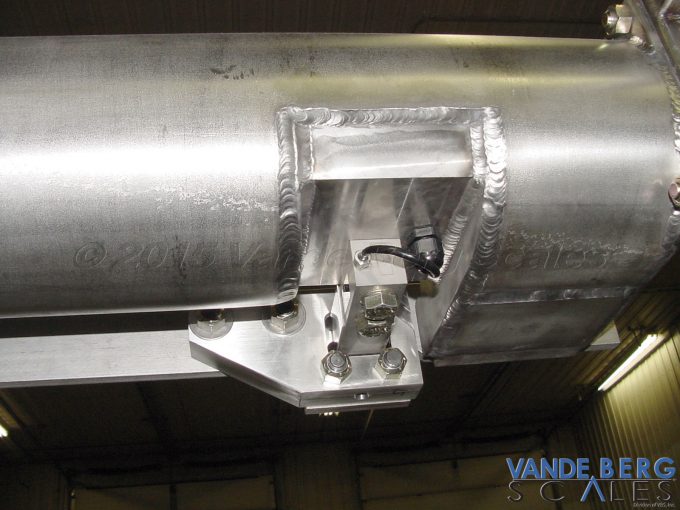

Technicians simply cut a small section from the existing rail system and bolt, or weld, the scale to the rail. Brackets are then placed from the scale to the wall or the ceiling.

Simultaneously weigh more than one trolley to decrease your total trolley weighing time. The long live rail is ideal for smokehouse applications that utilize multi-wheel trolley trees for moving product and multi-side weighing at one time. This scale is NOT NTEP.

Features & Benefits:

- 1,000-lb to 4,000-lb capacities allows tailoring to your needs

- Prefabricated bolt holes allow for easy installation and component replacement

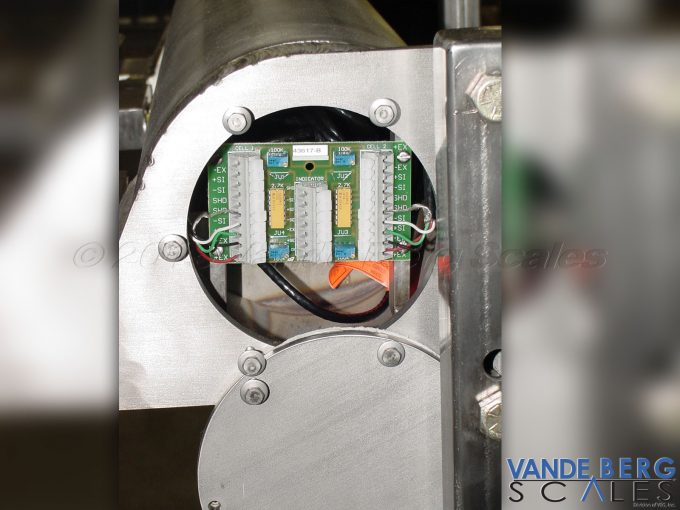

- Easily interfaces with a variety of weight indicators capable of 5,000 divisions

- Angular cut rail design maintains positive loading of both load cells at all points on the live rail

- Vast majority of cabling and summing electronics are safely enclosed in the stainless steel structure

- Changeable components include liverail, dead rails, rail-loading moon blocks

Static Multi-cell Monorail Features:

Innovative Design Reduces Weighing Errors

The live rail and live rail loading moon blocks have been specially designed to transition load onto the live rail in such a manner that both load cells will receive a positive load during transition eliminating the unloading of the far cell during initial trolley roll-on. This design will serve to stabilize the structure and provide better long term weighing results. The live rail is designed to float on radiused rail loading moon blocks to assure the inevitable deflection that occurs in the live rail will not translate to cosine weighing errors.

Watertight Construction

Stainless steel sealed load cells are used to repel water. The load cell cable exits the load cell then momentarily dips down to allow moisture to track to that drip point before raising and entering the hollow 6” diameter circular tube frame structure. The remainder of the load cell wiring is protected within the tubular frame structure terminating at the summing card. The weight indicator interface cable then exits the tube structure providing maximum cable protection.