Washdown Industrial Controller (SDS-1700)

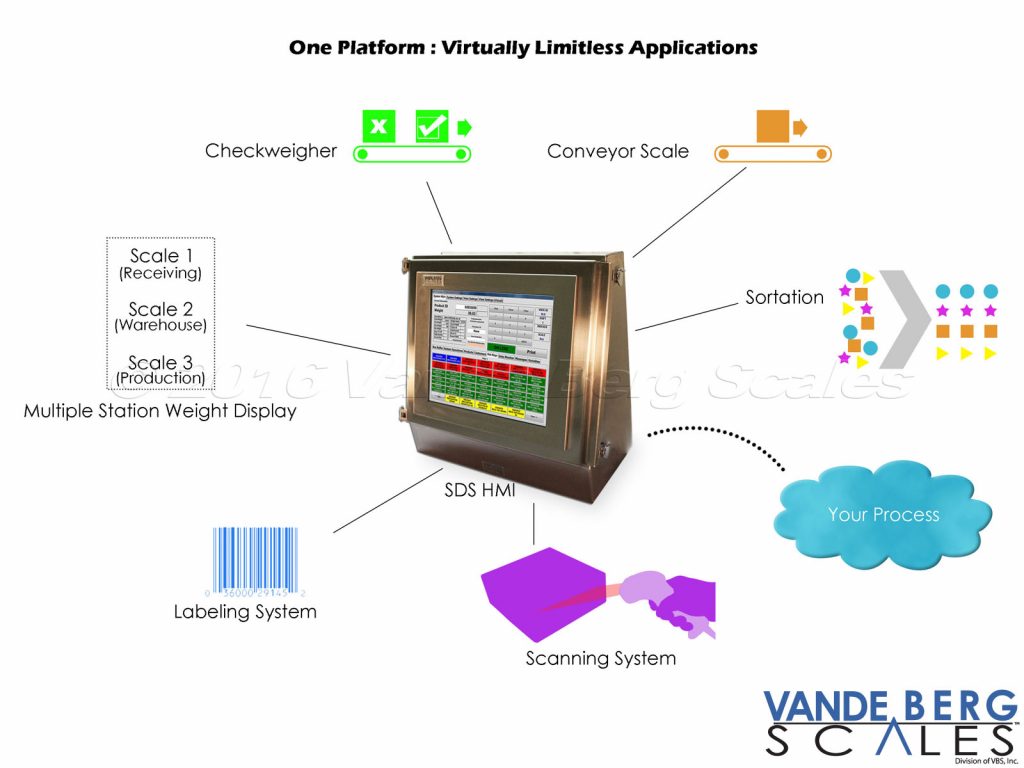

One platform…nearly limitless applications

Thoughtful Design Features:

Water stays out! – The touchscreen HMIs are equipped with a front maintenance access door featuring a rain gutter and recessed seals. This gains maintenance access to the NEMA-4X rated and sealed touchscreen monitor, optional internal mounted UPS, and the industrial embedded computer controller.

Keeping life simple – We have also designed the cable/cord seal to permit entry without cable end removal.

High temps? No problem. – It can also function in 105-deg F ambient temperatures.

You don’t want an industrial computer, you want the process functionality! You want it 1) to boot up fast, 2) to be robust, 3) to be tolerant of poor power, 4) to laugh at viruses and 5) to easily interface with your measuring equipment, if desired.

Features & Benefits:

- Windows® embedded operating system makes the build permanent and impervious to changes without formally committing the application.

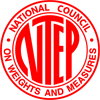

- Large touchscreen provides a positive interaction experience

- Modular, compact, robust design allows the SDS to be used standalone, connected to control enclosures and/or interfaced to weighing equipment.

- Watertight NEMA-4X stainless enclosure keeps components dry

- Lockable internal maintenance access keeps equipment secure

- Custom builds allow normal operating systems, if desired

SDS-1700 Controller Features:

FAQ

When using Windows® embedded, it’s simple – just pull the plug, wait 10 seconds and reinsert. The system will reboot to its original factory setting with no trace of a virus.

We can give you either .csv or resident MySQL data files for information storage and retrieval.

As long as our industrial controller is connected to the internet, remote login is possible. In fact, we recommend connecting to the internet in the off-chance that there is an issue that requires us to investigate. We can back-door into the system to see what is happening and help your team troubleshoot any issues.

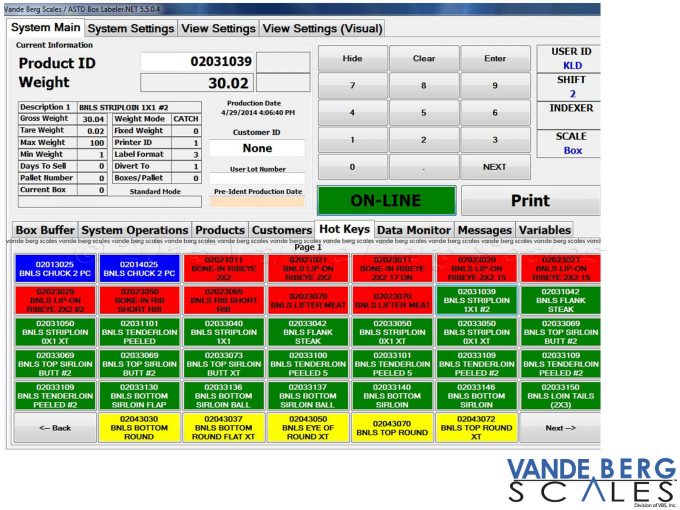

Yes – You can get the SDS with an NTEP approved weight indicator built right into the SDS with an approved metrological core eliminates the purchase of a separate weight indicator & enclosure. This simplifies the hardware solution.

NTEP is required when you are selling your product based on its weight. Therefore all food processing facilities require an NTEP scale in their facility when capturing product weight. NTEP is also required when transmitting a weight for creating a shipping label.

Do your applications have a rock solid equipment foundation?

The SDS unit represents a cornerstone for automated system uses. Uses include any computer-related tasks such as case/weigh-price/combo/barcode labeling, data entry stations, measurement process monitoring, operator process prompting, quality control, scale data interfacing, batching system control, traceability, remote displays, automatic ID, and more.

What is possible with this unit?

Operators can be prompted for specific data thereby minimizing thinking, writing, and decision making while transaction reliability is increased. If we write your application for you, we can customize the software to your exact needs. In addition, the SDS can run practically any or all of your existing Windows ® programs.

Our SDS industrial computer can be interfaced the same as any PC to equipment including keyboards, scanners, printers, fingerprint readers, Trolley Vision® readers, digital I/O, etc.

The SDS incorporates all the functionality of a computer in an industrial enclosure with easy to use 17-inch touchscreen HMI keeping the nuisance of mice and keyboards from your tough guys.