What is Angled-Roller Belting?

Angled-roller belting is a belt that can move a package to one side (left or right) of a conveyor, while simultaneously moving the package forward.

So why is angled roller belting useful? Having boxes along a common edge is vital for processes such as label printing/application, barcode scanning and box turning/redirection.

The image below shows angled roller belting with a guide rail.

The belt moves in the direction of green arrows, which carries the box/case forward. However, the rollers (blue arrows) will push the box against the guide rail so all boxes are presented along a common edge.

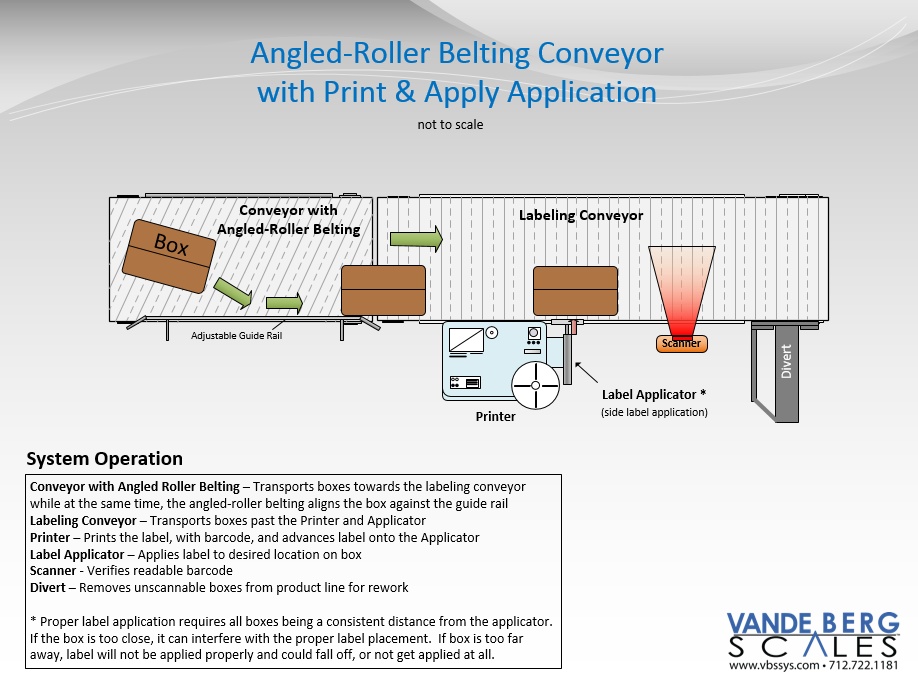

The image below shows boxes moving past a printer and scanner. The boxes are directed against the adjustable guide rail so they are a consistent distance from the label applicator.

Angled Roller Belting with Printer and Labeling System-PDF

Angled roller belting allows boxes to be presented in a consistent fashion resulting in uniform label application and reliable scanning.

See video below of how Angled-Roller Belting works.

Notice that the package moves forward while simultaneously aligning itself with the right edge of the conveyor.