How our Poultry Chain Scales work:

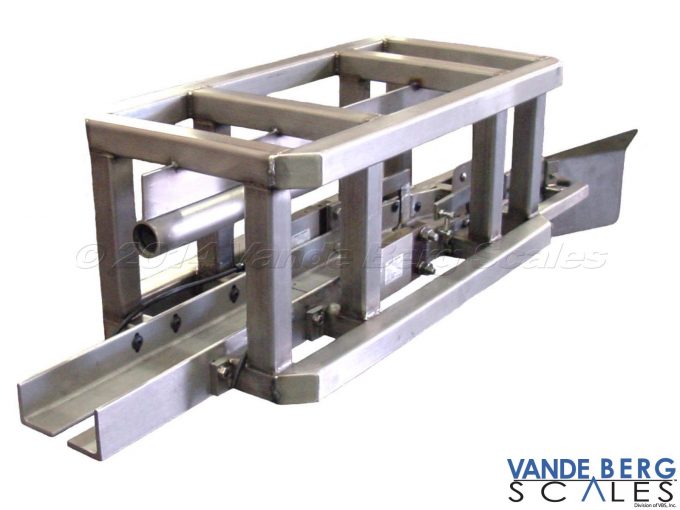

The plant chain supplies the propulsion and pulls the shackle roller of the linkage up onto the ramp leading to the weighing section. From this point the optional transition rail design gradually loads the live rail section of the scale. When the roller(s) are completely on the live section of the scale, a sensor is activated and the weighment cycle is started. The weighment cycle ends when a second sensor is activated just before the trolley leaves the live section of the scale.

The incline and rail design features a transition rail that gradually transfers highly concentrated shackle weight to the live rail thereby canceling out the undesirable spring oscillations inherent in other in-motion poultry chain scale designs.

The poultry chain scale system includes a specialized weight indicator which works in conjunction with the scale structure to perform multi-weighment averaging of the analog signals. Weight information is then sent to the host computer equipment, which enables a plant to determine and track individual birds weights automatically.

Why VBS poultry chain scales (monorails) are considered some of the best in the industry:

- Dual load cell design allows smallest possible scale divisions based on NTEP approved load cells

- Load cells are potted and encapsulated in a stainless steel cover and sealed to repel the environment

- Weight indicator included for system accuracy

- Highly stable weight based on mechanical design

Not sure what variables are important for specifying a poultry chain scale? No problem. Just fill out our questionnaire!

Poultry-Chain-Scale-Questionnaire.docx