Importance of Using and Infeed and Outfeed Conveyor

Checkweigher with infeed conveyor, conveyor scale and outfeed conveyor.

Q. Why does VBS recommend supplying the infeed and outfeed conveyor for their Checkweighers/Conveyor Scales?

A. The best way to explain this is to show how a checkweigher behaves when the customer supplies their own infeed and outfeed conveyor.

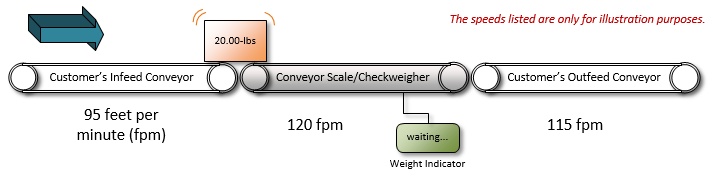

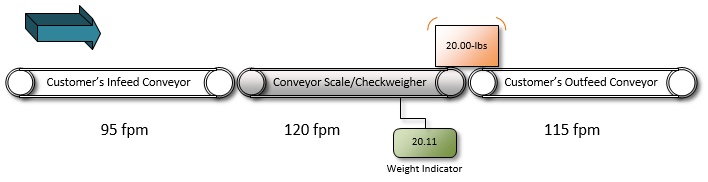

FACT: A customer’s infeed conveyor speed will rarely precisely match our conveyor scale speed. Even if these are off by just a few feet per minute, the following will occur.

As the orange box transfers from the infeed conveyor to our scale, the speed difference will create vibrations in the package to be weighed. The vibrations are created because two different belts are pulling on the same box.

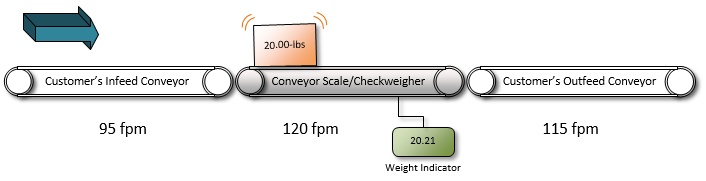

Although you cannot see the vibrations, they will continue even as the product fully transfers onto the scale, slowly and gradually over time subside. Our load cells are extremely sensitive and can pickup these vibrations as false weight.

The vibrations can endure until the product is well onto the scale just as it is ready to move onto the next conveyor. The sensitive load cells can be affected because of the tiny vibrations associated with the product.

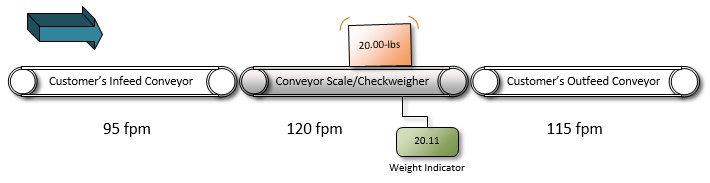

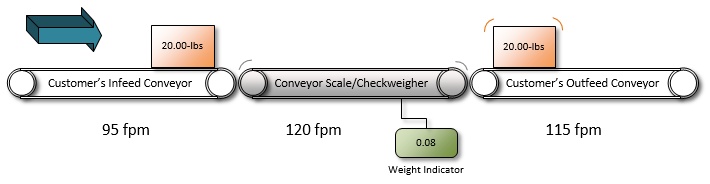

As the product transfers off the conveyor scale onto the outfeed conveyor, the speed difference again causes additional transfer vibrations. But this time a different action occurs.

The package vibration is transferred to the scale causing a ringing effect that can affect weighing the next box.

These very small vibrations have the potential to affect every weighment on your scale.

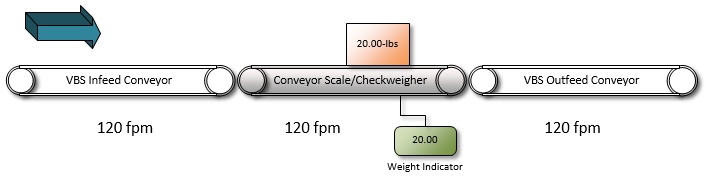

The only way to ensure absolutely accurate reading is for VBS to supply an infeed and outfeed scale whose belt speeds are EXACTLY matched.