How do products get properly spaced for weighing or labeling?

You need to use a box/case indexer. Proper product spacing is vital to ensuring reliable operation of downline equipment such as conveyor scales, checkweighers and labeling systems.

Conveyor Scale – proper product spacing ensures only one package is on the scale at a time. If two packages are simultaneously on the scale, an incorrect weight can result.

Checkweigher – A checkweigher is essentially a conveyor scale with a divert so the same incorrect weight situation will arise as with a conveyor scale. However, the divert may reject a package that is actually within the proper weight range.

Labeling System – Proper product spacing ensures that labels can be formatted, printed and applied to the box before the next one arrives.

So how exactly does an indexer work?

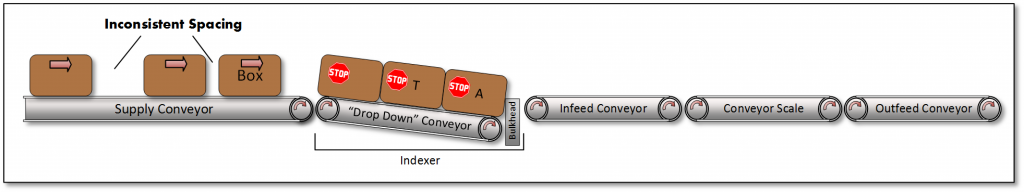

A supply conveyor transports boxes with inconsistent spacing. The boxes move onto the Indexer, which has a conveyor section that will drop down allowing boxes to accumulate against a Bulkhead. (This conveyor section has unique roller belting that allows the conveyor to continuously turn while boxes accumulate on top of the belt.)

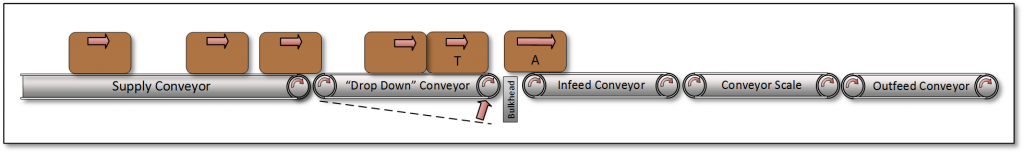

A sensor (not shown) detects a space is available, the Drop Down Conveyor section will then rise allowing a box to advance unobstructed. The Infeed Conveyor, which moves faster than the Drop Down Conveyor, will grab the first box (A) propelling it forward to create a gap between the trailing box (T).

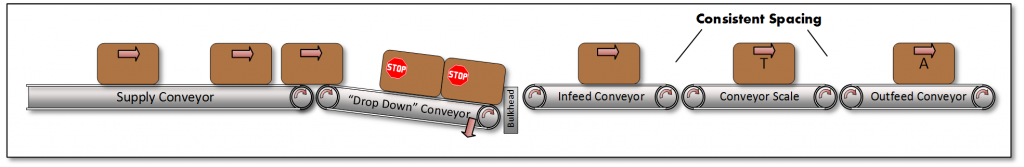

The Drop Down Conveyor will quickly lower again causing the boxes to accumulate against the bulkhead. Once the sensor (not shown) detects a gap, the indexer will rise, once again, and let another box advance. This is how an Indexer controls box spacing to ensure only one box is on the scale at a time.

Conclusion: Indexers are vital product handling equipment that can make your entire operation more efficient and reduce manual labor.